| Material specification | |

| Inside diameter (mm): | 80•100•130•150•180•200•250•300•350 |

| Outside diameter (mm): | 130•150•180•200•230•250•300•350•400 |

| Inner surface | 0.5 mm nominal thickness Quality 1.4404 (AISI 316L stainless steel) |

| Insulation | Rock wool panel, made of resin treated mineral fibres. 25 mm thick. 90/100 Kg/m3 density |

| Surface thermal resistance m2K/W at 200°C | 0,277•0,289•0,302•0,308•0,315•0,319•0,325•0,330•0,333 |

| Sealing ring | Profiled ring seal with three black silicone sealing lips conforming to UNI EN 14241/1 |

| Roughness | 1 mm average value |

| General information | |

| Installation | Internal Yes External YES it is rain proof |

| Fields of application | Pipes, chimneys, smoke ducts, flues and manifolds connected to blown air, atmospheric, condensation and pressurised boilers, type B, C appliances, fireplaces, stoves, kitchen hoods, ovens and ventilation ducts |

| Permitted fuels | T200 Gas, Diesel oil, LPG, Pellets T600 Gas, Diesel oil, LPG, Pellets and Firewood |

| Conservation | In environments with a non-corrosive atmosphere |

| Product warranty | As per the 99/44/EC directive |

| Dangerous substances | None |

| Freezing-thawing resistance | Meets UNI EN 1856-1 |

| Accidental contact | Protective shields must be used when the temperature of the fumes is about 300°C. In that the surface temperature is higher than 70°C |

| Storage | Do not store the material near ferrous materials, premises must be dry and protected against the elements |

| Usage limits | Do not use stainless steel flue systems for premises such as laundries, dye houses, furriers, printer’s, beauty salons or where there are halogen or chromium vapours/fumes |

| Product designation as per the EN 1856-1* standard: | Chimney system |

| No. of the standard | EN 1856-1 |

| Temperature level | T200 |

| Pressure level | P1 |

| Resistance to condensation | W |

| Resistance to corrosion | V2 |

| Thickness of the inner surface | L50050 |

| Resistance to fire from inside and distance from combustible materials | O (30 mm) D.350 O(45 mm) |

| Product designation as per the EN 1856-1 standard: | Smoke duct |

| No. of the standard | EN 1856-1 |

| Temperature level | T600 |

| Pressure level | N1 |

| Resistance to condensation | D |

| Resistance to corrosion | V2 |

| Thickness of the inner surface | L50050 |

| Resistance to fire from inside and distance from combustible materials | G (60 mm) Diam. 350 mm G (90 mm) |

| Performance required according to the designation | ||

| Temperature level | T200

T600 |

working with a nominal fumes temperature at less than 200°C working with a nominal fumes temperature at less than 600°C |

| Pressure level | P1

N1 |

working with a positive and negative pressure up to 200Pa. Permitted loss less than 0.006 l/m2 working with a positive and negative pressure up to 40Pa. Permitted loss less than 2.0l/sm2 |

| Resistance to condensation | W

D |

working with moist and dry fumes working with dry fumes |

| Resistance to corrosion | V2 | working with Gas-Diesel oil-LPG-Pellets-Firewood |

| Specification of the inner surface | L50 | 1.4404 (AISI 316L stainless steel) |

| Thickness of the inner surface | 050 | 0.5 mm nominal thickness |

| Resistance to fire from inside | O

G |

not fire resistant from inside resistant to fire from inside |

| Distance from combustible materials | (30)

(600) |

(30)=minimum 30mm. For diam. 350 it is 45mm (60)=minimum 60mm. For diam. 350 it is 90mm |

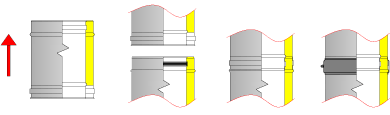

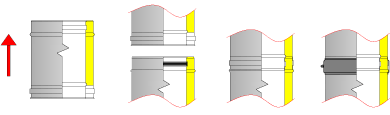

INSTALLATION INSTRUCTIONS

- Position the elements as shown by the arrow printed on the label and on the piece.

- With use at T200_P1_W put the sealing ring in place on the female socket.

- The three lips of the sealing ring must be facing the inside of the pipe.

- Use some talcum powder or soap to make it easier to put the ring in place and also to prevent damaging it.

- If T600_N1_D is used, use the product without the sealing ring.

- Once the pieces are in place, mount and tighten the locking clamp on each join.

- Observe the compression loads and the non-vertical installations.

- Avoid the build-up of condensation or soot which could be the cause of corrosion. Also avoid horizontal sections; nonetheless install the elements with the longitudinal welding facing up (3% gradient).

ESSENTIAL FEATURES

Resistance to the wind load:

- Distance between wall brackets: 2 m

- Free length from the last bracket: 1.5 m

Compressive strength:

- Linear elements’ maximum load: 12m

- Maximum load of a straight fitting at 90°: 12m

- Maximum load of the wall chimney support: 5m

Note: these values refer to the worst conditions. For more info see (Mechanical Strength Table)

30m Tensile and bending strength (linear elements):

- Maximum load at traction (element connection means and chimney connections): 3m

- Non-vertical installations: max. 45°

- Non-vertical installations: distance between wall chimney supports = 2m

Traction and bending strength (non-linear elements):

- Non-vertical installations: NPD

FLUE SYSTEM MAINTENANCE

Scheduled maintenance carried out by qualified personnel:

- Unless standards dictate otherwise or different agreements are reached with the user, the following maintenance schedule is advisable:

- gaseous fuels: 1 / year;

- liquid fuels: 1 / 6 months;

- solid fuels: 1 / month.

- Clean the smoke duct with a soft plastic brush or sponge as well as the equipment compartment for pipe supply and ventilation, the inspection fitting and chimney and also make sure the smoke/fumes and condensates etc., are flowing freely.

SYSTEM COMPONENTS

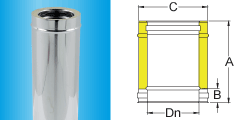

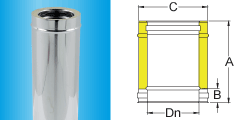

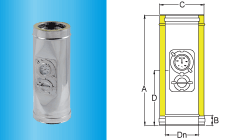

1 M LINEAR ELEMENT

995 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4460 0080 | 80 | 995 | 40 | 130 |

| 4460 0100 | 100 | 995 | 40 | 150 |

| 4460 0130 | 130 | 995 | 40 | 180 |

| 4460 0150 | 150 | 995 | 40 | 200 |

| 4460 0180 | 180 | 995 | 40 | 230 |

| 4460 0200 | 200 | 995 | 40 | 250 |

| 4460 0250 | 250 | 995 | 40 | 300 |

| 4460 0300 | 300 | 995 | 40 | 350 |

| 4460 0350 | 350 | 995 | 40 | 400 |

The Product Code of the copper finish is 4660. The rest of the Code that identifies the inside diameter remains the same.

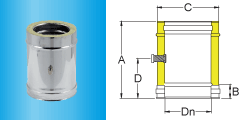

0,5 M LINEAR ELEMENT

495 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4455 0080 | 80 | 495 | 40 | 130 |

| 4455 0100 | 100 | 495 | 40 | 150 |

| 4455 0130 | 130 | 495 | 40 | 180 |

| 4455 0150 | 150 | 495 | 40 | 200 |

| 4455 0180 | 180 | 495 | 40 | 230 |

| 44550200 | 200 | 495 | 40 | 250 |

| 4455 0250 | 250 | 495 | 40 | 300 |

| 4455 0300 | 300 | 495 | 40 | 350 |

| 4455 0350 | 350 | 495 | 40 | 400 |

The Product Code of the copper finish is 4655. The rest of the Code that identifies the inside diameter remains the same.

0.25 M LINEAR ELEMENT

245 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4452 0080 | 80 | 245 | 40 | 130 |

| 4452 0100 | 100 | 245 | 40 | 150 |

| 4452 0130 | 130 | 245 | 40 | 180 |

| 4452 0150 | 150 | 245 | 40 | 200 |

| 4452 0180 | 180 | 245 | 40 | 230 |

| 4452 0200 | 200 | 245 | 40 | 250 |

| 4452 0250 | 250 | 245 | 40 | 300 |

| 4452 0300 | 300 | 245 | 40 | 350 |

| 4452 0350 | 350 | 245 | 40 | 400 |

The Product Code of the copper finish is 4653. The rest of the Code that identifies the inside diameter remains the same.

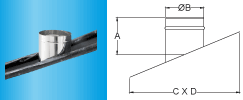

LINEAR TELESCOPIC ELEMENT FROM 0.5 TO 0.95

To use for completing sub-horizontal sections where standard linear elements cannot be used due to the enforced distance. It is indispensable to use a chimney support (art. 4567) in the case of vertical sections (above them). Product designation T450 N1 D V2 L50050 G(600).

| Code | Dn | A | B | C | D |

| 4586 0080 | 80 | 550 | 40 | 130 | 900 |

| 4586 0100 | 100 | 550 | 40 | 150 | 900 |

| 4586 0130 | 130 | 550 | 40 | 180 | 900 |

| 4586 0150 | 150 | 550 | 40 | 200 | 900 |

| 4586 0180 | 180 | 550 | 40 | 230 | 900 |

| 4586 0200 | 200 | 550 | 40 | 250 | 900 |

| 4586 0250 | 250 | 550 | 40 | 300 | 900 |

| 4586 0300 | 300 | 550 | 40 | 350 | 900 |

| 4586 0350 | 350 | 550 | 40 | 400 | 900 |

The Product Code of the copper finish is 4782. The rest of the Code that identifies the inside diameter remains the same.

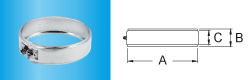

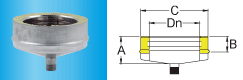

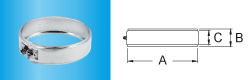

HIGH LOCKING CLAMP

This component is necessary for the joining of elements; it guarantees greater stability to the system.

| Code | Dn | A | B | C |

| 4551 0080 | 80 | 130 | 51 | 42 |

| 4551 0100 | 100 | 150 | 51 | 42 |

| 4551 0130 | 130 | 180 | 51 | 42 |

| 4551 0150 | 150 | 200 | 51 | 42 |

| 4551 0180 | 180 | 230 | 51 | 42 |

| 4551 0200 | 200 | 250 | 51 | 42 |

| 4551 0250 | 250 | 300 | 51 | 42 |

| 4551 0300 | 300 | 350 | 51 | 42 |

| 4551 0350 | 350 | 400 | 51 | 42 |

The Product Code of the copper finish is 4751. The rest of the Code that identifies the inside diameter remains the same.

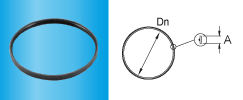

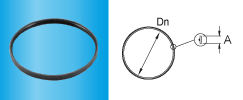

BLACK SEALING RING (T200)

Necessary for sealing the pipe, chimney, flue and smoke duct. Black colour, conforms to EN 14241/1 T200 W2 K2.

| Code | Dn | A |

| 4021 0080 | 80 | 12 |

| 4021 0100 | 100 | 12 |

| 4021 0130 | 130 | 12 |

| 4021 0150 | 150 | 12 |

| 4021 0180 | 180 | 12 |

| 4021 0200 | 200 | 12 |

| 4021 0250 | 250 | 12 |

| 4021 0300 | 300 | 12 |

| 4021 0350 | 350 | 12 |

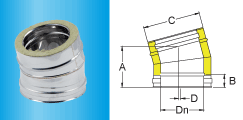

15° CURVE

Thanks to this component the vertical axis of the chimney, flue, pipe or smoke duct can be slanted 15°.

| Code | Dn | A | B | C | D |

| 4553 0080 | 80 | 132 | 40 | 130 | 23 |

| 4553 0100 | 100 | 134 | 40 | 150 | 23 |

| 4553 0130 | 130 | 132 | 40 | 180 | 23 |

| 4553 0150 | 150 | 134 | 40 | 200 | 23 |

| 4553 0180 | 180 | 144 | 40 | 230 | 24 |

| 4553 0200 | 200 | 147 | 40 | 250 | 25 |

| 4553 0250 | 250 | 147 | 40 | 300 | 25 |

| 4553 0300 | 300 | 147 | 40 | 350 | 25 |

| 4553 0350 | 350 | 147 | 40 | 400 | 25 |

The Product Code of the copper finish is 4779. The rest of the Code that identifies the inside diameter remains the same.

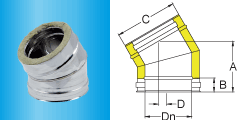

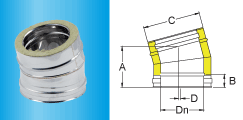

30° CURVE

Thanks to this component the vertical axis of the chimney, flue, pipe or smoke duct can be slanted 30°.

| Code | Dn | A | B | C | D |

| 4580 0080 | 80 | 147 | 40 | 130 | 29 |

| 4580 0100 | 100 | 152 | 40 | 150 | 30 |

| 4580 0130 | 130 | 147 | 40 | 180 | 29 |

| 4580 0150 | 150 | 152 | 40 | 200 | 30 |

| 4580 0180 | 180 | 160 | 40 | 230 | 32 |

| 4580 0200 | 200 | 177 | 40 | 250 | 37 |

| 4580 0250 | 250 | 177 | 40 | 300 | 37 |

| 4580 0300 | 300 | 198 | 40 | 350 | 42 |

| 4580 0350 | 350 | 198 | 40 | 400 | 42 |

The Product Code of the copper finish is 4780. The rest of the Code that identifies the inside diameter remains the same.

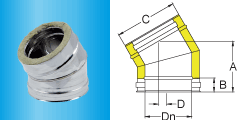

45° CURVE

Thanks to this component the vertical axis of the chimney, flue, pipe or smoke duct can be slanted 45°.

| Code | Dn | A | B | C | D |

| 4554 0080 | 80 | 153 | 40 | 130 | 46 |

| 4554 0100 | 100 | 160 | 40 | 150 | 49 |

| 4554 0130 | 130 | 153 | 40 | 180 | 46 |

| 4554 0150 | 150 | 160 | 40 | 200 | 49 |

| 4554 0180 | 180 | 170 | 40 | 230 | 53 |

| 4554 0200 | 200 | 196 | 40 | 250 | 63 |

| 4554 0250 | 250 | 196 | 40 | 300 | 63 |

| 4554 0300 | 300 | 231 | 40 | 350 | 78 |

| 4554 0350 | 350 | 231 | 40 | 400 | 78 |

The Product Code of the copper finish is 4754. The rest of the Code that identifies the inside diameter remains the same.

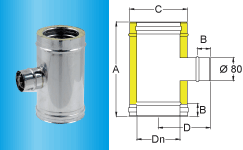

90° STRAIGHT FITTING Ø80 RED. (MALE COUPLING)

The chimney and flue can be connected at 90° with this component to the 80 diameter smoke duct. The peculiarity of this element is that it is made by extrusion meaning the couplings can be welded without any seams.

| Code | Dn | A | B | C | D | E |

| 4556 0080 | 80 | 328 | 40 | 130 | 145 | 124 |

| 4556 0100 | 100 | 328 | 40 | 150 | 155 | 124 |

| 4556 0130 | 130 | 328 | 40 | 180 | 170 | 124 |

| 4556 0150 | 150 | 328 | 40 | 200 | 180 | 124 |

| 4556 0180 | 180 | 328 | 40 | 230 | 195 | 124 |

| 4556 0200 | 200 | 328 | 40 | 250 | 205 | 124 |

| 4556 0250 | 250 | 328 | 40 | 300 | 230 | 124 |

| 4556 0300 | 300 | 328 | 40 | 350 | 255 | 124 |

| 4556 0350 | 350 | – | – | – | – | – |

The Product Code of the copper finish is 4783. The rest of the Code that identifies the inside diameter remains the same.

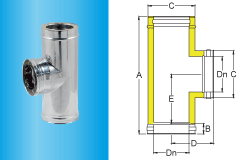

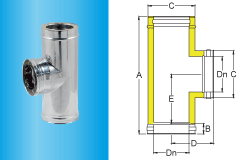

90° STRAIGHT FITTING (MALE COUPLING).

With this component the chimney and flue can be connected to the smoke duct at 90°. The peculiarity of this element is that it is made by extrusion meaning the couplings can be welded without any seams.

| Code | Dn | A | B | C | D | E |

| 4555 0080 | 80 | 328 | 40 | 130 | 145 | 124 |

| 4555 0100 | 100 | 328 | 40 | 150 | 155 | 124 |

| 4555 0130 | 130 | 495 | 40 | 180 | 170 | 208 |

| 4555 0150 | 150 | 495 | 40 | 200 | 180 | 208 |

| 4555 0180 | 180 | 495 | 40 | 230 | 195 | 208 |

| 4555 0200 | 200 | 495 | 40 | 250 | 205 | 208 |

| 4555 0250 | 250 | 495 | 40 | 300 | 230 | 208 |

| 4555 0300 | 300 | 495 | 40 | 350 | 255 | 208 |

| 4555 0350 | 350 | 595 | 40 | 400 | 280 | 258 |

The Product Code of the copper finish is 4756. The rest of the Code that identifies the inside diameter remains the same.

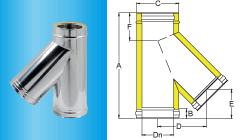

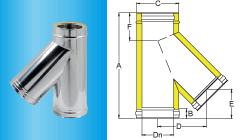

135° ANGLED FITTING (MALE COUPLING)

With this component the chimney and flue can be connected to the smoke duct at 135°. Product designation. T450 N1 D V2 L50050 G(75).

| Code | Dn | A | B | C | D | E | F |

| 4557 0080 | 80 | – | – | – | – | – | – |

| 4557 0100 | 100 | – | – | – | – | – | – |

| 4557 0130 | 130 | 495 | 40 | 180 | 233 | 145 | 118 |

| 4557 0150 | 150 | 495 | 40 | 200 | 233 | 142 | 130 |

| 4557 0180 | 180 | 495 | 40 | 230 | 233 | 145 | 118 |

| 4557 0200 | 200 | 615 | 40 | 250 | 304 | 162 | 150 |

| 4557 0250 | 250 | 615 | 40 | 300 | 304 | 162 | 150 |

| 4557 0300 | 300 | 760 | 40 | 350 | 388 | 194 | 178 |

| 4557 0350 | 350 | 760 | 40 | 400 | 388 | 194 | 178 |

The Product Code of the copper finish is 4757. The rest of the Code that identifies the inside diameter remains the same.

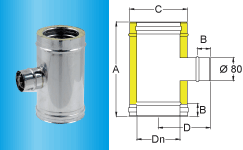

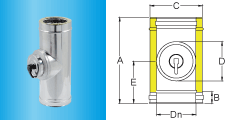

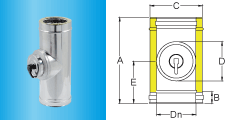

INSPECTION FITTING WITH SEALING PLUG

Necessary for cleaning and maintenance work; to be placed under the connections or as prescribed by the standard. Suitable for moist and positive pressure fumes: T200-P1-W.

| Code | Dn | A | B | C | D | E |

| 4558 0080 | 80 | 328 | 40 | 130 | 80 | 164 |

| 4558 0100 | 100 | 328 | 40 | 150 | 100 | 164 |

| 4558 0130 | 130 | 328 | 40 | 180 | 130 | 164 |

| 4558 0150 | 150 | 495 | 40 | 200 | 150 | 247,5 |

| 4558 0180 | 180 | 495 | 40 | 230 | 180 | 247,5 |

| 4558 0200 | 200 | 615 | 40 | 250 | 200 | 247,5 |

| 4558 0250 | 250 | 615 | 40 | 300 | 200 | 247,5 |

| 4558 0300 | 300 | 760 | 40 | 350 | 200 | 247,5 |

| 4558 0350 | 350 | 760 | 40 | 400 | 200 | 247,5 |

The Product Code of the copper finish is 4764. The rest of the Code that identifies the inside diameter remains the same.

INSPECTION FITTING WITH DOOR

Necessary for cleaning and maintenance work; to be placed at the base of the system. Suitable for dry and negative pressure fumes: Product designation T450 N1 D V2 L50050 G(75).

| Code | Dn | A | B | C | D | E | F |

| 4581 0080 | 80 | 495 | 40 | 130 | 248 | 113 | 190 |

| 4581 0100 | 100 | 495 | 40 | 150 | 248 | 113 | 190 |

| 4581 0130 | 130 | 495 | 40 | 180 | 248 | 113 | 190 |

| 4581 0150 | 150 | 495 | 40 | 200 | 248 | 113 | 190 |

| 4581 0180 | 180 | 495 | 40 | 230 | 248 | 200 | 290 |

| 4581 0200 | 200 | 495 | 40 | 250 | 248 | 200 | 290 |

| 4581 0250 | 250 | 495 | 40 | 300 | 248 | 200 | 290 |

| 4581 0300 | 300 | 495 | 40 | 350 | 248 | 162 | 222 |

| 4581 0350 | 350 | 495 | 40 | 400 | 248 | 162 | 222 |

The Product Code of the copper finish is 4789. The rest of the Code that identifies the inside diameter remains the same.

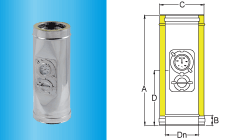

FUMES CONTROL FITTING WITH PLATE AND PYROMETER

Component used to control the temperature of the fumes and their quality. To place above the connections for suction pressure systems and higher than 35KW. Product designation T450 N1 D V2 L50050 G(75).

| Code | Dn | A | B | C | D |

| 4560 0080 | 80 | – | – | – | – |

| 4560 0100 | 100 | – | – | – | – |

| 4560 0130 | 130 | 495 | 40 | 180 | 247,5 |

| 4560 0150 | 150 | 495 | 40 | 200 | 247,5 |

| 4560 0180 | 180 | 495 | 40 | 230 | 247,5 |

| 4560 0200 | 200 | 495 | 40 | 250 | 247,5 |

| 4560 0250 | 250 | 495 | 40 | 300 | 247,5 |

| 4560 0300 | 300 | 495 | 40 | 350 | 247,5 |

| 4560 0350 | 350 | 495 | 40 | 400 | 247,5 |

The Product Code of the copper finish is 4784. The rest of the Code that identifies the inside diameter remains the same.

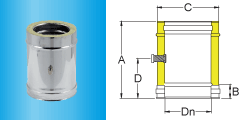

ELEMENT WITH SCREW FOR FUMES ANALYSIS

Component used to measure the internal pressures and control the temperature of the fumes and their quality.

| Code | Dn | A | B | C | D |

| 4561 0080 | 80 | 245 | 40 | 130 | 122,5 |

| 4561 0100 | 100 | 245 | 40 | 150 | 122,5 |

| 4561 0130 | 130 | 245 | 40 | 180 | 122,5 |

| 4561 0150 | 150 | 245 | 40 | 200 | 122,5 |

| 4561 0180 | 180 | 245 | 40 | 230 | 122,5 |

| 4561 0200 | 200 | 245 | 40 | 250 | 122,5 |

| 4561 0250 | 250 | 245 | 40 | 300 | 122,5 |

| 4561 0300 | 300 | 245 | 40 | 350 | 122,5 |

| 4561 0350 | 350 | 245 | 40 | 400 | 122,5 |

The Product Code of the copper finish is 4763. The rest of the Code that identifies the inside diameter remains the same.

WINDPROOF CHIMNEY CAP

To be placed on the top; it protects against the rain, snow and wind.

| Code | Dn | A | B | C | D | E |

| 4563 0080 | 80 | 215 | 40 | 130 | 250 | 137 |

| 4563 0100 | 100 | 215 | 40 | 150 | 250 | 137 |

| 4563 0130 | 130 | 215 | 40 | 180 | 300 | 137 |

| 4563 0150 | 150 | 283 | 40 | 200 | 300 | 195 |

| 4563 0180 | 180 | 283 | 40 | 230 | 400 | 195 |

| 4563 0200 | 200 | 283 | 40 | 250 | 400 | 195 |

| 4563 0250 | 250 | 333 | 40 | 300 | 500 | 245 |

| 4563 0300 | 300 | 415 | 40 | 350 | 550 | 328 |

| 4563 0350 | 350 | 415 | 40 | 400 | 600 | 328 |

The Product Code of the copper finish is 4768. The rest of the Code that identifies the inside diameter remains the same.

CONICAL CHIMNEY CAP

To be placed on the top; it does not protect against the rain, snow or wind. It allows the fumes to be discharged without obstacles or pressure losses.

| Code | Dn | A | B | C |

| 4564 0080 | 80 | 165 | 40 | 130 |

| 4564 0100 | 100 | 165 | 40 | 150 |

| 4564 0130 | 130 | 165 | 40 | 180 |

| 4564 0150 | 150 | 165 | 40 | 200 |

| 4564 0180 | 180 | 165 | 40 | 230 |

| 4564 0200 | 200 | 165 | 40 | 250 |

| 4564 0250 | 250 | 165 | 40 | 300 |

| 4564 0300 | 300 | 165 | 40 | 350 |

| 4564 0350 | 350 | 165 | 40 | 400 |

The Product Code of the copper finish is 4776. The rest of the Code that identifies the inside diameter remains the same.

CHINESE CHIMNEY CAP

Component to place on the top; it provides sufficient protection against rain and snow.

| Code | Dn | A | B | C | D |

| 4562 0080 | 80 | 165 | 40 | 130 | 216 |

| 4562 0100 | 100 | 170 | 40 | 150 | 216 |

| 4562 0130 | 130 | 177 | 40 | 180 | 276 |

| 4562 0150 | 150 | 210 | 40 | 200 | 335 |

| 4562 0180 | 180 | 215 | 40 | 230 | 335 |

| 4562 0200 | 200 | 220 | 40 | 250 | 396 |

| 4562 0250 | 250 | 264 | 40 | 300 | 463 |

| 4562 0300 | 300 | 271 | 40 | 350 | 463 |

| 4562 0350 | 350 | 271 | 40 | 400 | 600 |

The Product Code of the copper finish is 4767. The rest of the Code that identifies the inside diameter remains the same.

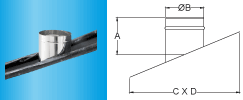

SLAB FINISHING DUAL WALL FLAT PLATE

Component used together with the dual wall system can be used to go through roofs, structures or wooden walls or any other combustible material. It may also be made on a slant (art.45393).

| Code | Dn | A | B | C | D |

| 45391 0080 | 80 | 200 | 330 | 320 | 150 |

| 45391 0100 | 100 | 200 | 330 | 320 | 170 |

| 45391 0130 | 130 | 200 | 330 | 485 | 200 |

| 45391 0150 | 150 | 200 | 330 | 485 | 220 |

| 45391 0180 | 180 | 200 | 330 | 485 | 250 |

| 45391 0200 | 200 | 200 | 330 | 485 | 270 |

| 45391 0250 | 250 | 200 | 330 | 485 | 320 |

| 45391 0300 | 300 | 200 | 330 | 485 | 370 |

| 45391 0350 | 350 | 200 | 330 | 485 | 420 |

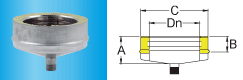

EAVES PLATE

Component to place at the base of the chimney; its peculiarity is that it is made by swaging a flat disk. Moreover, the condensate discharge is made in stainless steel, ¾” thread and is welded in place.

| Code | Dn | A | B | C |

| 4565 0080 | 80 | 85 | 40 | 130 |

| 4565 0100 | 100 | 89 | 40 | 150 |

| 4565 0130 | 130 | 95 | 40 | 180 |

| 4565 0150 | 150 | 98 | 40 | 200 |

| 4565 0180 | 180 | 95 | 40 | 230 |

| 4565 0200 | 200 | 109 | 40 | 250 |

| 4565 0250 | 250 | 107 | 40 | 300 |

| 4565 0300 | 300 | 112 | 40 | 350 |

| 4565 0350 | 350 | 115 | 40 | 400 |

The Product Code of the copper finish is 4759. The rest of the Code that identifies the inside diameter remains the same.

EAVES PLATE WITH SUPPORTING BASE

Component with the same features as the eaves plate art.4565. In addition, it has a supporting base with hole so the system can stand on the ground and discharge condensation horizontally.

| Code | Dn | A | B | C |

| 4566 0080 | 80 | 220 | 40 | 130 |

| 4566 0100 | 100 | 220 | 40 | 150 |

| 4566 0130 | 130 | 220 | 40 | 180 |

| 4566 0150 | 150 | 220 | 40 | 200 |

| 4566 0180 | 180 | 220 | 40 | 230 |

| 4566 0200 | 200 | 220 | 40 | 250 |

| 4566 0250 | 250 | 220 | 40 | 300 |

| 4566 0300 | 300 | 220 | 40 | 350 |

| 4566 0350 | 350 | 220 | 40 | 400 |

The Product Code of the copper finish is 4785. The rest of the Code that identifies the inside diameter remains the same.

0° OUTLET ELEMENT

Component fixed to the ground allowing the system to be supported.

| Code | Dn | A | B | C | D | E |

| 4579 0080 | 80 | 160 | 40 | 130 | 250 | 241 |

| 4579 0100 | 100 | 160 | 40 | 150 | 250 | 241 |

| 4579 0130 | 130 | 160 | 40 | 180 | 320 | 320 |

| 4579 0150 | 150 | 160 | 40 | 200 | 320 | 320 |

| 4579 0180 | 180 | 160 | 40 | 230 | 320 | 320 |

| 4579 0200 | 200 | 160 | 40 | 250 | 320 | 320 |

| 4579 0250 | 250 | 160 | 40 | 300 | 400 | 400 |

| 4579 0300 | 300 | 160 | 40 | 350 | 480 | 480 |

| 4579 0350 | 350 | 160 | 40 | 400 | 480 | 480 |

The Product Code of the copper finish is 4760. The rest of the Code that identifies the inside diameter remains the same.

CHIMNEY WALL SUPPORT

Component necessary to support the system

| Code | Dn | A | B | C | D | E | F | G | H | I |

| 4567 0080 | 80 | 160 | 40 | 130 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4567 0100 | 100 | 160 | 40 | 150 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4567 0130 | 130 | 160 | 40 | 180 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4567 0150 | 150 | 160 | 40 | 200 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4567 0180 | 180 | 160 | 40 | 230 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4567 0200 | 200 | 160 | 40 | 250 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4567 0250 | 250 | 160 | 40 | 300 | 352 | 370 | 522 | 412 | 185 | 265 |

| 4567 0300 | 300 | 160 | 40 | 350 | 452 | 470 | 692 | 512 | 235 | 315 |

| 4567 0350 | 350 | 160 | 40 | 400 | 452 | 470 | 692 | 512 | 235 | 315 |

The Product Code of the copper finish is 4778. The rest of the Code that identifies the inside diameter remains the same.

CONVERSE WITH A 5°/30° SLANT, WATERPROOF MEMBRANE BASE

To use on roofs with a 5 to 30° slant and coupled with the converse covering, code 4512. . . – prevents water from infiltrating. The 2.3 mm thick base is lead-free and waterproof. Once applied it must be sealed on tiles, bricks, glass, etc., with a continuous layer of glue.

| Code | Dn | A | B | C | D |

| 4584 0080 | 80 | 155 | 160 | 600 | 1000 |

| 4584 0100 | 100 | 155 | 180 | 600 | 1000 |

| 4584 0130 | 130 | 180 | 230 | 600 | 1000 |

| 4584 0150 | 150 | 180 | 250 | 800 | 1000 |

| 4584 0180 | 180 | 180 | 270 | 800 | 1000 |

| 4584 0200 | 200 | 245 | 300 | 800 | 1000 |

| 4584 0250 | 250 | 245 | 350 | 1000 | 1000 |

| 4584 0300 | 300 | 245 | 400 | 1000 | 1000 |

| 4584 0350 | 350 | 245 | 450 | 1000 | 1000 |

The Product Code of the copper finish is 4787. The rest of the Code that identifies the inside diameter remains the same.

0° FLAT CONVERSE, WATERPROOF MEMBRANE BASE

To use on flat roofs and coupled with the converse covering, code 4512. . . – prevents water from infiltrating. The 2.3 mm thick base is lead-free and waterproof. Once applied it must be sealed on tiles, bricks, glass, etc., with a continuous layer of glue.

| Code | Dn | A | B | C | D |

| 4585 0080 | 80 | 155 | 160 | 500 | 1000 |

| 4585 0100 | 100 | 155 | 180 | 500 | 1000 |

| 4585 0130 | 130 | 180 | 230 | 500 | 1000 |

| 4585 0150 | 150 | 180 | 250 | 500 | 1000 |

| 4585 0180 | 180 | 180 | 270 | 625 | 1000 |

| 4585 0200 | 200 | 245 | 300 | 325 | 1000 |

| 4585 0250 | 250 | 245 | 350 | 715 | 1000 |

| 4585 0300 | 300 | 245 | 400 | 715 | 1000 |

| 4585 0350 | 350 | 245 | 450 | 715 | 1000 |

The Product Code of the copper finish is 4788. The rest of the Code that identifies the inside diameter remains the same.

CONVERSE COVERING

This component is to be used as flashing to tighten on the pipe. Coupled with converse code 4584. . . . and code 4585. . . – prevents water from infiltrating.

| Code | Dn | A | B |

| 4512 0130 | 130 | 60 | 220 |

| 4512 0150 | 150 | 60 | 240 |

| 4512 0180 | 180 | 60 | 320 |

| 4512 0200 | 200 | 60 | 320 |

| 4512 0230 | 230 | 60 | 320 |

| 4512 0250 | 250 | 60 | 370 |

| 4512 0300 | 300 | 60 | 420 |

| 4512 0350 | 350 | 60 | 480 |

| 4512 0400 | 400 | 60 | 520 |

The Product Code of the copper finish is 4762. The rest of the Code that identifies the inside diameter remains the same.

FEMALE DUAL WALL TO MALE SINGLE WALL ADAPTER

This component is necessary to go from a dual wall to a single wall system.

| Code | Dn | A | B | C |

| 4576 0080 | 80 | 160 | 40 | 130 |

| 4576 0100 | 100 | 160 | 40 | 150 |

| 4576 0130 | 130 | 160 | 40 | 180 |

| 4576 0150 | 150 | 160 | 40 | 200 |

| 4576 0180 | 180 | 160 | 40 | 230 |

| 4576 0200 | 200 | 160 | 40 | 250 |

| 4576 0250 | 250 | 160 | 40 | 300 |

| 4576 0300 | 300 | 160 | 40 | 350 |

| 4576 0350 | 350 | 160 | 40 | 400 |

|

DARK BROWN MATT DAMASK EFFECT (RAL 8017)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN MATT DARK BROWN (RAL 8017)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN BLACKIf temperatures exceed 450° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN WHITE (RAL 9010)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |

MAIN FEATURES

- Inner surface in 0.5mm thick AISI 316L BA stainless steel;

- MAT DP: Outer surface in 0.5mm thick AISI 316L BA stainless steel;

- DP COPPER: Copper outer wall;

- Rock wool insulation made with a blend of basalt mixes treated with phenol-based thermosetting resins and anti-dust emulsion additive, 25 mm thick, density of 90/100 Kg/m3;

- Complete range.

MAIN FEATURES

- Inner surface in 0.5mm thick AISI 316L BA stainless steel;

- MAT DP: Outer surface in 0.5mm thick AISI 316L BA stainless steel;

- DP COPPER: Copper outer wall;

- Rock wool insulation made with a blend of basalt mixes treated with phenol-based thermosetting resins and anti-dust emulsion additive, 25 mm thick, density of 90/100 Kg/m3;

- Complete range.

| Material specification | |

| Inside diameter (mm): | 80•100•130•150•180•200•250•300•350 |

| Outside diameter (mm): | 130•150•180•200•230•250•300•350•400 |

| Inner surface | 0.5 mm nominal thickness Quality 1.4404 (AISI 316L stainless steel) |

| Insulation | Rock wool panel, made of resin treated mineral fibres. 25 mm thick. 90/100 Kg/m3 density |

| Surface thermal resistance m2K/W at 200°C | 0,277•0,289•0,302•0,308•0,315•0,319•0,325•0,330•0,333 |

| Sealing ring | Profiled ring seal with three black silicone sealing lips conforming to UNI EN 14241/1 |

| Roughness | 1 mm average value |

| General information | |

| Installation | Internal Yes External YES it is rain proof |

| Fields of application | Pipes, chimneys, smoke ducts, flues and manifolds connected to blown air, atmospheric, condensation and pressurised boilers, type B, C appliances, fireplaces, stoves, kitchen hoods, ovens and ventilation ducts |

| Permitted fuels | T200 Gas, Diesel oil, LPG, Pellets T600 Gas, Diesel oil, LPG, Pellets and Firewood |

| Conservation | In environments with a non-corrosive atmosphere |

| Product warranty | As per the 99/44/EC directive |

| Dangerous substances | None |

| Freezing-thawing resistance | Meets UNI EN 1856-1 |

| Accidental contact | Protective shields must be used when the temperature of the fumes is about 300°C. In that the surface temperature is higher than 70°C |

| Storage | Do not store the material near ferrous materials, premises must be dry and protected against the elements |

| Usage limits | Do not use stainless steel flue systems for premises such as laundries, dye houses, furriers, printer’s, beauty salons or where there are halogen or chromium vapours/fumes |

| Product designation as per the EN 1856-1* standard: | Chimney system |

| No. of the standard | EN 1856-1 |

| Temperature level | T200 |

| Pressure level | P1 |

| Resistance to condensation | W |

| Resistance to corrosion | V2 |

| Thickness of the inner surface | L50050 |

| Resistance to fire from inside and distance from combustible materials | O (30 mm) D.350 O(45 mm) |

| Product designation as per the EN 1856-1 standard: | Smoke duct |

| No. of the standard | EN 1856-1 |

| Temperature level | T600 |

| Pressure level | N1 |

| Resistance to condensation | D |

| Resistance to corrosion | V2 |

| Thickness of the inner surface | L50050 |

| Resistance to fire from inside and distance from combustible materials | G (60 mm) Diam. 350 mm G (90 mm) |

| Performance required according to the designation | ||

| Temperature level | T200

T600 |

working with a nominal fumes temperature at less than 200°C working with a nominal fumes temperature at less than 600°C |

| Pressure level | P1

N1 |

working with a positive and negative pressure up to 200Pa. Permitted loss less than 0.006 l/m2 working with a positive and negative pressure up to 40Pa. Permitted loss less than 2.0l/sm2 |

| Resistance to condensation | W

D |

working with moist and dry fumes working with dry fumes |

| Resistance to corrosion | V2 | working with Gas-Diesel oil-LPG-Pellets-Firewood |

| Specification of the inner surface | L50 | 1.4404 (AISI 316L stainless steel) |

| Thickness of the inner surface | 050 | 0.5 mm nominal thickness |

| Resistance to fire from inside | O

G |

not fire resistant from inside resistant to fire from inside |

| Distance from combustible materials | (30)

(600) |

(30)=minimum 30mm. For diam. 350 it is 45mm (60)=minimum 60mm. For diam. 350 it is 90mm |

INSTALLATION INSTRUCTIONS

- Position the elements as shown by the arrow printed on the label and on the piece.

- With use at T200_P1_W put the sealing ring in place on the female socket.

- The three lips of the sealing ring must be facing the inside of the pipe.

- Use some talcum powder or soap to make it easier to put the ring in place and also to prevent damaging it.

- If T600_N1_D is used, use the product without the sealing ring.

- Once the pieces are in place, mount and tighten the locking clamp on each join.

- Observe the compression loads and the non-vertical installations.

- Avoid the build-up of condensation or soot which could be the cause of corrosion. Also avoid horizontal sections; nonetheless install the elements with the longitudinal welding facing up (3% gradient).

ESSENTIAL FEATURES

Resistance to the wind load:

- Distance between wall brackets: 2 m

- Free length from the last bracket: 1.5 m

Compressive strength:

- Linear elements’ maximum load: 12m

- Maximum load of a straight fitting at 90°: 12m

- Maximum load of the wall chimney support: 5m

Note: these values refer to the worst conditions. For more info see (Mechanical Strength Table)

30m Tensile and bending strength (linear elements):

- Maximum load at traction (element connection means and chimney connections): 3m

- Non-vertical installations: max. 45°

- Non-vertical installations: distance between wall chimney supports = 2m

Traction and bending strength (non-linear elements):

- Non-vertical installations: NPD

FLUE SYSTEM MAINTENANCE

Scheduled maintenance carried out by qualified personnel:

- Unless standards dictate otherwise or different agreements are reached with the user, the following maintenance schedule is advisable:

- gaseous fuels: 1 / year;

- liquid fuels: 1 / 6 months;

- solid fuels: 1 / month.

- Clean the smoke duct with a soft plastic brush or sponge as well as the equipment compartment for pipe supply and ventilation, the inspection fitting and chimney and also make sure the smoke/fumes and condensates etc., are flowing freely.

SYSTEM COMPONENTS

1 M LINEAR ELEMENT

995 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4460 0080 | 80 | 995 | 40 | 130 |

| 4460 0100 | 100 | 995 | 40 | 150 |

| 4460 0130 | 130 | 995 | 40 | 180 |

| 4460 0150 | 150 | 995 | 40 | 200 |

| 4460 0180 | 180 | 995 | 40 | 230 |

| 4460 0200 | 200 | 995 | 40 | 250 |

| 4460 0250 | 250 | 995 | 40 | 300 |

| 4460 0300 | 300 | 995 | 40 | 350 |

| 4460 0350 | 350 | 995 | 40 | 400 |

The Product Code of the copper finish is 4660. The rest of the Code that identifies the inside diameter remains the same.

0,5 M LINEAR ELEMENT

495 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4455 0080 | 80 | 495 | 40 | 130 |

| 4455 0100 | 100 | 495 | 40 | 150 |

| 4455 0130 | 130 | 495 | 40 | 180 |

| 4455 0150 | 150 | 495 | 40 | 200 |

| 4455 0180 | 180 | 495 | 40 | 230 |

| 44550200 | 200 | 495 | 40 | 250 |

| 4455 0250 | 250 | 495 | 40 | 300 |

| 4455 0300 | 300 | 495 | 40 | 350 |

| 4455 0350 | 350 | 495 | 40 | 400 |

The Product Code of the copper finish is 4655. The rest of the Code that identifies the inside diameter remains the same.

0.25 M LINEAR ELEMENT

245 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4452 0080 | 80 | 245 | 40 | 130 |

| 4452 0100 | 100 | 245 | 40 | 150 |

| 4452 0130 | 130 | 245 | 40 | 180 |

| 4452 0150 | 150 | 245 | 40 | 200 |

| 4452 0180 | 180 | 245 | 40 | 230 |

| 4452 0200 | 200 | 245 | 40 | 250 |

| 4452 0250 | 250 | 245 | 40 | 300 |

| 4452 0300 | 300 | 245 | 40 | 350 |

| 4452 0350 | 350 | 245 | 40 | 400 |

The Product Code of the copper finish is 4653. The rest of the Code that identifies the inside diameter remains the same.

LINEAR TELESCOPIC ELEMENT FROM 0.5 TO 0.95

To use for completing sub-horizontal sections where standard linear elements cannot be used due to the enforced distance. It is indispensable to use a chimney support (art. 4567) in the case of vertical sections (above them). Product designation T450 N1 D V2 L50050 G(600).

| Code | Dn | A | B | C | D |

| 4586 0080 | 80 | 550 | 40 | 130 | 900 |

| 4586 0100 | 100 | 550 | 40 | 150 | 900 |

| 4586 0130 | 130 | 550 | 40 | 180 | 900 |

| 4586 0150 | 150 | 550 | 40 | 200 | 900 |

| 4586 0180 | 180 | 550 | 40 | 230 | 900 |

| 4586 0200 | 200 | 550 | 40 | 250 | 900 |

| 4586 0250 | 250 | 550 | 40 | 300 | 900 |

| 4586 0300 | 300 | 550 | 40 | 350 | 900 |

| 4586 0350 | 350 | 550 | 40 | 400 | 900 |

The Product Code of the copper finish is 4782. The rest of the Code that identifies the inside diameter remains the same.

HIGH LOCKING CLAMP

This component is necessary for the joining of elements; it guarantees greater stability to the system.

| Code | Dn | A | B | C |

| 4551 0080 | 80 | 130 | 51 | 42 |

| 4551 0100 | 100 | 150 | 51 | 42 |

| 4551 0130 | 130 | 180 | 51 | 42 |

| 4551 0150 | 150 | 200 | 51 | 42 |

| 4551 0180 | 180 | 230 | 51 | 42 |

| 4551 0200 | 200 | 250 | 51 | 42 |

| 4551 0250 | 250 | 300 | 51 | 42 |

| 4551 0300 | 300 | 350 | 51 | 42 |

| 4551 0350 | 350 | 400 | 51 | 42 |

The Product Code of the copper finish is 4751. The rest of the Code that identifies the inside diameter remains the same.

BLACK SEALING RING (T200)

Necessary for sealing the pipe, chimney, flue and smoke duct. Black colour, conforms to EN 14241/1 T200 W2 K2.

| Code | Dn | A |

| 4021 0080 | 80 | 12 |

| 4021 0100 | 100 | 12 |

| 4021 0130 | 130 | 12 |

| 4021 0150 | 150 | 12 |

| 4021 0180 | 180 | 12 |

| 4021 0200 | 200 | 12 |

| 4021 0250 | 250 | 12 |

| 4021 0300 | 300 | 12 |

| 4021 0350 | 350 | 12 |

15° CURVE

Thanks to this component the vertical axis of the chimney, flue, pipe or smoke duct can be slanted 15°.

| Code | Dn | A | B | C | D |

| 4553 0080 | 80 | 132 | 40 | 130 | 23 |

| 4553 0100 | 100 | 134 | 40 | 150 | 23 |

| 4553 0130 | 130 | 132 | 40 | 180 | 23 |

| 4553 0150 | 150 | 134 | 40 | 200 | 23 |

| 4553 0180 | 180 | 144 | 40 | 230 | 24 |

| 4553 0200 | 200 | 147 | 40 | 250 | 25 |

| 4553 0250 | 250 | 147 | 40 | 300 | 25 |

| 4553 0300 | 300 | 147 | 40 | 350 | 25 |

| 4553 0350 | 350 | 147 | 40 | 400 | 25 |

The Product Code of the copper finish is 4779. The rest of the Code that identifies the inside diameter remains the same.

30° CURVE

Thanks to this component the vertical axis of the chimney, flue, pipe or smoke duct can be slanted 30°.

| Code | Dn | A | B | C | D |

| 4580 0080 | 80 | 147 | 40 | 130 | 29 |

| 4580 0100 | 100 | 152 | 40 | 150 | 30 |

| 4580 0130 | 130 | 147 | 40 | 180 | 29 |

| 4580 0150 | 150 | 152 | 40 | 200 | 30 |

| 4580 0180 | 180 | 160 | 40 | 230 | 32 |

| 4580 0200 | 200 | 177 | 40 | 250 | 37 |

| 4580 0250 | 250 | 177 | 40 | 300 | 37 |

| 4580 0300 | 300 | 198 | 40 | 350 | 42 |

| 4580 0350 | 350 | 198 | 40 | 400 | 42 |

The Product Code of the copper finish is 4780. The rest of the Code that identifies the inside diameter remains the same.

45° CURVE

Thanks to this component the vertical axis of the chimney, flue, pipe or smoke duct can be slanted 45°.

| Code | Dn | A | B | C | D |

| 4554 0080 | 80 | 153 | 40 | 130 | 46 |

| 4554 0100 | 100 | 160 | 40 | 150 | 49 |

| 4554 0130 | 130 | 153 | 40 | 180 | 46 |

| 4554 0150 | 150 | 160 | 40 | 200 | 49 |

| 4554 0180 | 180 | 170 | 40 | 230 | 53 |

| 4554 0200 | 200 | 196 | 40 | 250 | 63 |

| 4554 0250 | 250 | 196 | 40 | 300 | 63 |

| 4554 0300 | 300 | 231 | 40 | 350 | 78 |

| 4554 0350 | 350 | 231 | 40 | 400 | 78 |

The Product Code of the copper finish is 4754. The rest of the Code that identifies the inside diameter remains the same.

90° STRAIGHT FITTING Ø80 RED. (MALE COUPLING)

The chimney and flue can be connected at 90° with this component to the 80 diameter smoke duct. The peculiarity of this element is that it is made by extrusion meaning the couplings can be welded without any seams.

| Code | Dn | A | B | C | D | E |

| 4556 0080 | 80 | 328 | 40 | 130 | 145 | 124 |

| 4556 0100 | 100 | 328 | 40 | 150 | 155 | 124 |

| 4556 0130 | 130 | 328 | 40 | 180 | 170 | 124 |

| 4556 0150 | 150 | 328 | 40 | 200 | 180 | 124 |

| 4556 0180 | 180 | 328 | 40 | 230 | 195 | 124 |

| 4556 0200 | 200 | 328 | 40 | 250 | 205 | 124 |

| 4556 0250 | 250 | 328 | 40 | 300 | 230 | 124 |

| 4556 0300 | 300 | 328 | 40 | 350 | 255 | 124 |

| 4556 0350 | 350 | – | – | – | – | – |

The Product Code of the copper finish is 4783. The rest of the Code that identifies the inside diameter remains the same.

90° STRAIGHT FITTING (MALE COUPLING).

With this component the chimney and flue can be connected to the smoke duct at 90°. The peculiarity of this element is that it is made by extrusion meaning the couplings can be welded without any seams.

| Code | Dn | A | B | C | D | E |

| 4555 0080 | 80 | 328 | 40 | 130 | 145 | 124 |

| 4555 0100 | 100 | 328 | 40 | 150 | 155 | 124 |

| 4555 0130 | 130 | 495 | 40 | 180 | 170 | 208 |

| 4555 0150 | 150 | 495 | 40 | 200 | 180 | 208 |

| 4555 0180 | 180 | 495 | 40 | 230 | 195 | 208 |

| 4555 0200 | 200 | 495 | 40 | 250 | 205 | 208 |

| 4555 0250 | 250 | 495 | 40 | 300 | 230 | 208 |

| 4555 0300 | 300 | 495 | 40 | 350 | 255 | 208 |

| 4555 0350 | 350 | 595 | 40 | 400 | 280 | 258 |

The Product Code of the copper finish is 4756. The rest of the Code that identifies the inside diameter remains the same.

135° ANGLED FITTING (MALE COUPLING)

With this component the chimney and flue can be connected to the smoke duct at 135°. Product designation. T450 N1 D V2 L50050 G(75).

| Code | Dn | A | B | C | D | E | F |

| 4557 0080 | 80 | – | – | – | – | – | – |

| 4557 0100 | 100 | – | – | – | – | – | – |

| 4557 0130 | 130 | 495 | 40 | 180 | 233 | 145 | 118 |

| 4557 0150 | 150 | 495 | 40 | 200 | 233 | 142 | 130 |

| 4557 0180 | 180 | 495 | 40 | 230 | 233 | 145 | 118 |

| 4557 0200 | 200 | 615 | 40 | 250 | 304 | 162 | 150 |

| 4557 0250 | 250 | 615 | 40 | 300 | 304 | 162 | 150 |

| 4557 0300 | 300 | 760 | 40 | 350 | 388 | 194 | 178 |

| 4557 0350 | 350 | 760 | 40 | 400 | 388 | 194 | 178 |

The Product Code of the copper finish is 4757. The rest of the Code that identifies the inside diameter remains the same.

INSPECTION FITTING WITH SEALING PLUG

Necessary for cleaning and maintenance work; to be placed under the connections or as prescribed by the standard. Suitable for moist and positive pressure fumes: T200-P1-W.

| Code | Dn | A | B | C | D | E |

| 4558 0080 | 80 | 328 | 40 | 130 | 80 | 164 |

| 4558 0100 | 100 | 328 | 40 | 150 | 100 | 164 |

| 4558 0130 | 130 | 328 | 40 | 180 | 130 | 164 |

| 4558 0150 | 150 | 495 | 40 | 200 | 150 | 247,5 |

| 4558 0180 | 180 | 495 | 40 | 230 | 180 | 247,5 |

| 4558 0200 | 200 | 615 | 40 | 250 | 200 | 247,5 |

| 4558 0250 | 250 | 615 | 40 | 300 | 200 | 247,5 |

| 4558 0300 | 300 | 760 | 40 | 350 | 200 | 247,5 |

| 4558 0350 | 350 | 760 | 40 | 400 | 200 | 247,5 |

The Product Code of the copper finish is 4764. The rest of the Code that identifies the inside diameter remains the same.

INSPECTION FITTING WITH DOOR

Necessary for cleaning and maintenance work; to be placed at the base of the system. Suitable for dry and negative pressure fumes: Product designation T450 N1 D V2 L50050 G(75).

| Code | Dn | A | B | C | D | E | F |

| 4581 0080 | 80 | 495 | 40 | 130 | 248 | 113 | 190 |

| 4581 0100 | 100 | 495 | 40 | 150 | 248 | 113 | 190 |

| 4581 0130 | 130 | 495 | 40 | 180 | 248 | 113 | 190 |

| 4581 0150 | 150 | 495 | 40 | 200 | 248 | 113 | 190 |

| 4581 0180 | 180 | 495 | 40 | 230 | 248 | 200 | 290 |

| 4581 0200 | 200 | 495 | 40 | 250 | 248 | 200 | 290 |

| 4581 0250 | 250 | 495 | 40 | 300 | 248 | 200 | 290 |

| 4581 0300 | 300 | 495 | 40 | 350 | 248 | 162 | 222 |

| 4581 0350 | 350 | 495 | 40 | 400 | 248 | 162 | 222 |

The Product Code of the copper finish is 4789. The rest of the Code that identifies the inside diameter remains the same.

FUMES CONTROL FITTING WITH PLATE AND PYROMETER

Component used to control the temperature of the fumes and their quality. To place above the connections for suction pressure systems and higher than 35KW. Product designation T450 N1 D V2 L50050 G(75).

| Code | Dn | A | B | C | D |

| 4560 0080 | 80 | – | – | – | – |

| 4560 0100 | 100 | – | – | – | – |

| 4560 0130 | 130 | 495 | 40 | 180 | 247,5 |

| 4560 0150 | 150 | 495 | 40 | 200 | 247,5 |

| 4560 0180 | 180 | 495 | 40 | 230 | 247,5 |

| 4560 0200 | 200 | 495 | 40 | 250 | 247,5 |

| 4560 0250 | 250 | 495 | 40 | 300 | 247,5 |

| 4560 0300 | 300 | 495 | 40 | 350 | 247,5 |

| 4560 0350 | 350 | 495 | 40 | 400 | 247,5 |

The Product Code of the copper finish is 4784. The rest of the Code that identifies the inside diameter remains the same.

ELEMENT WITH SCREW FOR FUMES ANALYSIS

Component used to measure the internal pressures and control the temperature of the fumes and their quality.

| Code | Dn | A | B | C | D |

| 4561 0080 | 80 | 245 | 40 | 130 | 122,5 |

| 4561 0100 | 100 | 245 | 40 | 150 | 122,5 |

| 4561 0130 | 130 | 245 | 40 | 180 | 122,5 |

| 4561 0150 | 150 | 245 | 40 | 200 | 122,5 |

| 4561 0180 | 180 | 245 | 40 | 230 | 122,5 |

| 4561 0200 | 200 | 245 | 40 | 250 | 122,5 |

| 4561 0250 | 250 | 245 | 40 | 300 | 122,5 |

| 4561 0300 | 300 | 245 | 40 | 350 | 122,5 |

| 4561 0350 | 350 | 245 | 40 | 400 | 122,5 |

The Product Code of the copper finish is 4763. The rest of the Code that identifies the inside diameter remains the same.

WINDPROOF CHIMNEY CAP

To be placed on the top; it protects against the rain, snow and wind.

| Code | Dn | A | B | C | D | E |

| 4563 0080 | 80 | 215 | 40 | 130 | 250 | 137 |

| 4563 0100 | 100 | 215 | 40 | 150 | 250 | 137 |

| 4563 0130 | 130 | 215 | 40 | 180 | 300 | 137 |

| 4563 0150 | 150 | 283 | 40 | 200 | 300 | 195 |

| 4563 0180 | 180 | 283 | 40 | 230 | 400 | 195 |

| 4563 0200 | 200 | 283 | 40 | 250 | 400 | 195 |

| 4563 0250 | 250 | 333 | 40 | 300 | 500 | 245 |

| 4563 0300 | 300 | 415 | 40 | 350 | 550 | 328 |

| 4563 0350 | 350 | 415 | 40 | 400 | 600 | 328 |

The Product Code of the copper finish is 4768. The rest of the Code that identifies the inside diameter remains the same.

CONICAL CHIMNEY CAP

To be placed on the top; it does not protect against the rain, snow or wind. It allows the fumes to be discharged without obstacles or pressure losses.

| Code | Dn | A | B | C |

| 4564 0080 | 80 | 165 | 40 | 130 |

| 4564 0100 | 100 | 165 | 40 | 150 |

| 4564 0130 | 130 | 165 | 40 | 180 |

| 4564 0150 | 150 | 165 | 40 | 200 |

| 4564 0180 | 180 | 165 | 40 | 230 |

| 4564 0200 | 200 | 165 | 40 | 250 |

| 4564 0250 | 250 | 165 | 40 | 300 |

| 4564 0300 | 300 | 165 | 40 | 350 |

| 4564 0350 | 350 | 165 | 40 | 400 |

The Product Code of the copper finish is 4776. The rest of the Code that identifies the inside diameter remains the same.

CHINESE CHIMNEY CAP

Component to place on the top; it provides sufficient protection against rain and snow.

| Code | Dn | A | B | C | D |

| 4562 0080 | 80 | 165 | 40 | 130 | 216 |

| 4562 0100 | 100 | 170 | 40 | 150 | 216 |

| 4562 0130 | 130 | 177 | 40 | 180 | 276 |

| 4562 0150 | 150 | 210 | 40 | 200 | 335 |

| 4562 0180 | 180 | 215 | 40 | 230 | 335 |

| 4562 0200 | 200 | 220 | 40 | 250 | 396 |

| 4562 0250 | 250 | 264 | 40 | 300 | 463 |

| 4562 0300 | 300 | 271 | 40 | 350 | 463 |

| 4562 0350 | 350 | 271 | 40 | 400 | 600 |

The Product Code of the copper finish is 4767. The rest of the Code that identifies the inside diameter remains the same.

SLAB FINISHING DUAL WALL FLAT PLATE

Component used together with the dual wall system can be used to go through roofs, structures or wooden walls or any other combustible material. It may also be made on a slant (art.45393).

| Code | Dn | A | B | C | D |

| 45391 0080 | 80 | 200 | 330 | 320 | 150 |

| 45391 0100 | 100 | 200 | 330 | 320 | 170 |

| 45391 0130 | 130 | 200 | 330 | 485 | 200 |

| 45391 0150 | 150 | 200 | 330 | 485 | 220 |

| 45391 0180 | 180 | 200 | 330 | 485 | 250 |

| 45391 0200 | 200 | 200 | 330 | 485 | 270 |

| 45391 0250 | 250 | 200 | 330 | 485 | 320 |

| 45391 0300 | 300 | 200 | 330 | 485 | 370 |

| 45391 0350 | 350 | 200 | 330 | 485 | 420 |

EAVES PLATE

Component to place at the base of the chimney; its peculiarity is that it is made by swaging a flat disk. Moreover, the condensate discharge is made in stainless steel, ¾” thread and is welded in place.

| Code | Dn | A | B | C |

| 4565 0080 | 80 | 85 | 40 | 130 |

| 4565 0100 | 100 | 89 | 40 | 150 |

| 4565 0130 | 130 | 95 | 40 | 180 |

| 4565 0150 | 150 | 98 | 40 | 200 |

| 4565 0180 | 180 | 95 | 40 | 230 |

| 4565 0200 | 200 | 109 | 40 | 250 |

| 4565 0250 | 250 | 107 | 40 | 300 |

| 4565 0300 | 300 | 112 | 40 | 350 |

| 4565 0350 | 350 | 115 | 40 | 400 |

The Product Code of the copper finish is 4759. The rest of the Code that identifies the inside diameter remains the same.

EAVES PLATE WITH SUPPORTING BASE

Component with the same features as the eaves plate art.4565. In addition, it has a supporting base with hole so the system can stand on the ground and discharge condensation horizontally.

| Code | Dn | A | B | C |

| 4566 0080 | 80 | 220 | 40 | 130 |

| 4566 0100 | 100 | 220 | 40 | 150 |

| 4566 0130 | 130 | 220 | 40 | 180 |

| 4566 0150 | 150 | 220 | 40 | 200 |

| 4566 0180 | 180 | 220 | 40 | 230 |

| 4566 0200 | 200 | 220 | 40 | 250 |

| 4566 0250 | 250 | 220 | 40 | 300 |

| 4566 0300 | 300 | 220 | 40 | 350 |

| 4566 0350 | 350 | 220 | 40 | 400 |

The Product Code of the copper finish is 4785. The rest of the Code that identifies the inside diameter remains the same.

0° OUTLET ELEMENT

Component fixed to the ground allowing the system to be supported.

| Code | Dn | A | B | C | D | E |

| 4579 0080 | 80 | 160 | 40 | 130 | 250 | 241 |

| 4579 0100 | 100 | 160 | 40 | 150 | 250 | 241 |

| 4579 0130 | 130 | 160 | 40 | 180 | 320 | 320 |

| 4579 0150 | 150 | 160 | 40 | 200 | 320 | 320 |

| 4579 0180 | 180 | 160 | 40 | 230 | 320 | 320 |

| 4579 0200 | 200 | 160 | 40 | 250 | 320 | 320 |

| 4579 0250 | 250 | 160 | 40 | 300 | 400 | 400 |

| 4579 0300 | 300 | 160 | 40 | 350 | 480 | 480 |

| 4579 0350 | 350 | 160 | 40 | 400 | 480 | 480 |

The Product Code of the copper finish is 4760. The rest of the Code that identifies the inside diameter remains the same.

CHIMNEY WALL SUPPORT

Component necessary to support the system

| Code | Dn | A | B | C | D | E | F | G | H | I |

| 4567 0080 | 80 | 160 | 40 | 130 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4567 0100 | 100 | 160 | 40 | 150 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4567 0130 | 130 | 160 | 40 | 180 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4567 0150 | 150 | 160 | 40 | 200 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4567 0180 | 180 | 160 | 40 | 230 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4567 0200 | 200 | 160 | 40 | 250 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4567 0250 | 250 | 160 | 40 | 300 | 352 | 370 | 522 | 412 | 185 | 265 |

| 4567 0300 | 300 | 160 | 40 | 350 | 452 | 470 | 692 | 512 | 235 | 315 |

| 4567 0350 | 350 | 160 | 40 | 400 | 452 | 470 | 692 | 512 | 235 | 315 |

The Product Code of the copper finish is 4778. The rest of the Code that identifies the inside diameter remains the same.

CONVERSE WITH A 5°/30° SLANT, WATERPROOF MEMBRANE BASE

To use on roofs with a 5 to 30° slant and coupled with the converse covering, code 4512. . . – prevents water from infiltrating. The 2.3 mm thick base is lead-free and waterproof. Once applied it must be sealed on tiles, bricks, glass, etc., with a continuous layer of glue.

| Code | Dn | A | B | C | D |

| 4584 0080 | 80 | 155 | 160 | 600 | 1000 |

| 4584 0100 | 100 | 155 | 180 | 600 | 1000 |

| 4584 0130 | 130 | 180 | 230 | 600 | 1000 |

| 4584 0150 | 150 | 180 | 250 | 800 | 1000 |

| 4584 0180 | 180 | 180 | 270 | 800 | 1000 |

| 4584 0200 | 200 | 245 | 300 | 800 | 1000 |

| 4584 0250 | 250 | 245 | 350 | 1000 | 1000 |

| 4584 0300 | 300 | 245 | 400 | 1000 | 1000 |

| 4584 0350 | 350 | 245 | 450 | 1000 | 1000 |

The Product Code of the copper finish is 4787. The rest of the Code that identifies the inside diameter remains the same.

0° FLAT CONVERSE, WATERPROOF MEMBRANE BASE

To use on flat roofs and coupled with the converse covering, code 4512. . . – prevents water from infiltrating. The 2.3 mm thick base is lead-free and waterproof. Once applied it must be sealed on tiles, bricks, glass, etc., with a continuous layer of glue.

| Code | Dn | A | B | C | D |

| 4585 0080 | 80 | 155 | 160 | 500 | 1000 |

| 4585 0100 | 100 | 155 | 180 | 500 | 1000 |

| 4585 0130 | 130 | 180 | 230 | 500 | 1000 |

| 4585 0150 | 150 | 180 | 250 | 500 | 1000 |

| 4585 0180 | 180 | 180 | 270 | 625 | 1000 |

| 4585 0200 | 200 | 245 | 300 | 325 | 1000 |

| 4585 0250 | 250 | 245 | 350 | 715 | 1000 |

| 4585 0300 | 300 | 245 | 400 | 715 | 1000 |

| 4585 0350 | 350 | 245 | 450 | 715 | 1000 |

The Product Code of the copper finish is 4788. The rest of the Code that identifies the inside diameter remains the same.

CONVERSE COVERING

This component is to be used as flashing to tighten on the pipe. Coupled with converse code 4584. . . . and code 4585. . . – prevents water from infiltrating.

| Code | Dn | A | B |

| 4512 0130 | 130 | 60 | 220 |

| 4512 0150 | 150 | 60 | 240 |

| 4512 0180 | 180 | 60 | 320 |

| 4512 0200 | 200 | 60 | 320 |

| 4512 0230 | 230 | 60 | 320 |

| 4512 0250 | 250 | 60 | 370 |

| 4512 0300 | 300 | 60 | 420 |

| 4512 0350 | 350 | 60 | 480 |

| 4512 0400 | 400 | 60 | 520 |

The Product Code of the copper finish is 4762. The rest of the Code that identifies the inside diameter remains the same.

FEMALE DUAL WALL TO MALE SINGLE WALL ADAPTER

This component is necessary to go from a dual wall to a single wall system.

| Code | Dn | A | B | C |

| 4576 0080 | 80 | 160 | 40 | 130 |

| 4576 0100 | 100 | 160 | 40 | 150 |

| 4576 0130 | 130 | 160 | 40 | 180 |

| 4576 0150 | 150 | 160 | 40 | 200 |

| 4576 0180 | 180 | 160 | 40 | 230 |

| 4576 0200 | 200 | 160 | 40 | 250 |

| 4576 0250 | 250 | 160 | 40 | 300 |

| 4576 0300 | 300 | 160 | 40 | 350 |

| 4576 0350 | 350 | 160 | 40 | 400 |

|

DARK BROWN MATT DAMASK EFFECT (RAL 8017)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN MATT DARK BROWN (RAL 8017)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN BLACKIf temperatures exceed 450° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN WHITE (RAL 9010)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |