| Material specification | |

| Inside diameter (mm)*: | 80•100•120•140•160•180•200•230 |

| Outside diameter (mm)*. | 100•120•140•160•180•200•230•250 |

| Inner surface | 0.5 mm nominal thickness Quality 1.4404 (AISI 316L stainless steel) |

| Insulation | 10 mm air gap with surface thermal resistance of 200°C equal to a dry air conductivity of: 0.026 m2K/W (300 K, 100 kPa) |

| Sealing ring | Profiled ring seal with three black silicone sealing lips conforming to UNI EN 14241/1 |

| Roughness | 1 mm average value |

| General information | |

| Installation | Internal Yes External YES it is rain proof |

| Fields of application | Pipes, chimneys, smoke ducts, flues and manifolds connected to blown air, atmospheric, condensation and pressurised boilers, type B, C appliances, fireplaces, stoves, kitchen hoods, ovens and ventilation ducts |

| Permitted fuels | T200 Gas, Diesel oil, LPG, Pellets T600 Gas, Diesel oil, LPG, Pellets and Firewood |

| Conservation | In environments with a non-corrosive atmosphere |

| Product warranty | As per the 99/44/EC directive |

| Dangerous substances | None |

| Freezing-thawing resistance | Meets UNI EN 1856-1 |

| Accidental contact | Protective shields must be used when surface temperature is greater than 70°C |

| Storage | Do not store the material near ferrous materials, premises must be dry and protected against the elements |

| Usage limits | Do not use stainless steel flue systems for premises such as laundries, dye houses, furriers, printer’s, beauty salons or where there are halogen or chromium vapours/fumes |

| Product designation as per the EN 1856-2 standard | Chimney system |

| No. of the standard | EN 1856-1 |

| Temperature level | T200 |

| Pressure level | P1 |

| Resistance to condensation | W |

| Resistance to corrosion | V2 |

| Thickness of the inner surface | L50050 |

| Resistance to fire from inside and distance from combustible materials | O (30) M |

| Product designation as per the EN 1856-2 standard: | Canale da fumo |

| No. of the standard | EN 1856-1 |

| Temperature level | T600 |

| Pressure level | N1 |

| Resistance to condensation | D |

| Resistance to corrosion | V2 |

| Thickness of the inner surface | L50050 |

| Resistance to fire from inside and distance from combustible materials | G(600) M |

| Performance required according to the designation | ||

| Temperature level | T200

T600 |

working with a nominal fumes temperature at less than 200°C working with a nominal fumes temperature at less than 600°C |

| Pressure level | P1

N1 |

working with a positive and negative pressure up to 200Pa. Permitted loss less than 0.006 l/m2 working with a positive and negative pressure up to 40Pa. Permitted loss less than 2.0l/sm2 |

| Resistance to condensation | W

D |

working with moist and dry fumes working with dry fumes |

| Resistance to corrosion | V2 | working with Gas-Diesel oil-LPG-Pellets-Firewood |

| Specification of the inner surface | L50 | 1.4404 (AISI 316L stainless steel) |

| Thickness of the inner surface | 050 | spessore nominale 0,5 mm |

| Resistance to fire from inside | O

G |

not fire resistant from inside resistant to fire from inside |

| Distance from combustible materials | (30)

(600) |

(30)=minimum 30mm; (600)=minimum 600mm; |

INSTALLATION INSTRUCTIONS

- Position the elements as shown by the arrow printed on the label and on the piece.

- With use at T200_P1_W put the sealing ring in place on the female socket.

- The three lips of the sealing ring must be facing the inside of the pipe.

- Use some talcum powder or soap to make it easier to put the ring in place and also to prevent damaging it.

- If T600_N1_D is used, use the product without the sealing ring.

- Once the pieces are in place, mount and tighten the locking clamp on each join.

- Observe the compression loads and the non-vertical installations.

- Avoid the build-up of condensation or soot which could be the cause of corrosion. Also avoid horizontal sections; nonetheless install the elements with the longitudinal welding facing up (3% gradient).

ESSENTIAL FEATURES

Resistance to the wind load:

- Distance between wall brackets: 2 m

- Free length from the last bracket: 1.5 m

Compressive strength:

- Linear elements’ maximum load: 12m

- Maximum load of a straight fitting at 90°: 12m

- Maximum load of the wall chimney support: 5m

Note: these values refer to the worst conditions. For more info see (Mechanical Strength Table)

30m Tensile and bending strength (linear elements):

- Maximum load at traction (element connection means and chimney connections): 3m

- Non-vertical installations: max. 45°

- Non-vertical installations: distance between wall chimney supports = 2m

Traction and bending strength (non-linear elements):

- Non-vertical installations: NPD

FLUE SYSTEM MAINTENANCE

Scheduled maintenance carried out by qualified personnel:

- Unless standards dictate otherwise or different agreements are reached with the user, the following maintenance schedule is advisable:

- gaseous fuels: 1 / year;

- liquid fuels: 1 / 6 months;

- solid fuels: 1 / month.

- Clean the smoke duct with a soft plastic brush or sponge as well as the equipment compartment for pipe supply and ventilation, the inspection fitting and chimney and also make sure the smoke/fumes and condensates etc., are flowing freely.

SYSTEM COMPONENTS

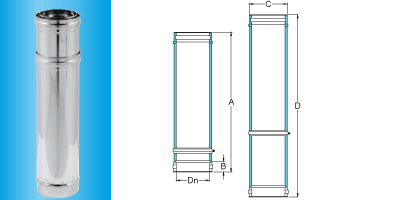

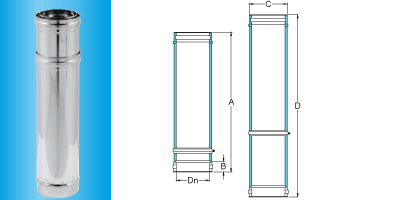

1 M LINEAR ELEMENT

995 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4810 0080 | 80 | 995 | 40 | 100 |

| 4810 0100 | 100 | 995 | 40 | 120 |

| 4810 0120 | 120 | 995 | 40 | 140 |

| 4810 0140 | 140 | 995 | 40 | 160 |

| 4810 0160 | 160 | 995 | 40 | 180 |

| 4810 0180 | 180 | 995 | 40 | 200 |

| 4810 0200 | 200 | 995 | 40 | 230 |

| 4810 0230 | 230 | 995 | 40 | 250 |

0.5 M LINEAR ELEMENT

495 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4805 0080 | 80 | 495 | 40 | 100 |

| 4805 0100 | 100 | 495 | 40 | 120 |

| 4805 0120 | 120 | 495 | 40 | 140 |

| 4805 0140 | 140 | 495 | 40 | 160 |

| 4805 0160 | 160 | 495 | 40 | 180 |

| 4805 0180 | 180 | 495 | 40 | 200 |

| 4805 0200 | 200 | 495 | 40 | 230 |

| 4805 0230 | 230 | 495 | 40 | 250 |

0.25 M LINEAR ELEMENT

245 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4802 0080 | 80 | 245 | 40 | 100 |

| 4802 0100 | 100 | 245 | 40 | 120 |

| 4802 0120 | 120 | 245 | 40 | 140 |

| 4802 0140 | 140 | 245 | 40 | 160 |

| 4802 0160 | 160 | 245 | 40 | 180 |

| 4802 0180 | 180 | 245 | 40 | 200 |

| 4802 0200 | 200 | 245 | 40 | 230 |

| 4802 0230 | 230 | 245 | 40 | 250 |

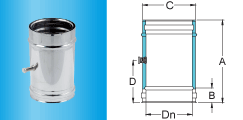

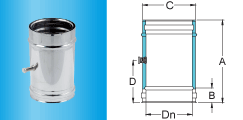

LINEAR TELESCOPIC ELEMENT FROM 0.5 TO 0.95

To use for completing sub-horizontal sections where standard linear elements cannot be used due to the enforced distance. It is indispensable to use a chimney support (art. 4567) in the case of vertical sections (above them). Product designation T450 N1 D V2 L50050 G(600).

| Code | Dn | A | B | C | D |

| 4822 0080 | 80 | 550 | 40 | 100 | 900 |

| 4822 0100 | 100 | 550 | 40 | 120 | 900 |

| 4822 0120 | 120 | 550 | 40 | 140 | 900 |

| 4822 0140 | 140 | 550 | 40 | 160 | 900 |

| 4822 0160 | 160 | 550 | 40 | 180 | 900 |

| 4822 0180 | 180 | 550 | 40 | 200 | 900 |

| 4822 0200 | 200 | 550 | 40 | 230 | 900 |

| 4822 0230 | 230 | 550 | 40 | 250 | 900 |

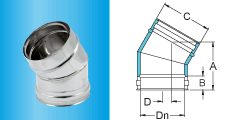

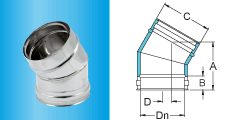

30° CURVE

Thanks to this component the vertical axis of the chimney, flue, pipe or smoke duct can be slanted 30°.

| Code | Dn | A | B | C | D |

| 4820 0080 | 80 | 187 | 40 | 100 | 50 |

| 4820 0100 | 100 | 179 | 40 | 120 | 48 |

| 4820 0120 | 120 | 170 | 40 | 140 | 45 |

| 4820 0140 | 140 | 187 | 40 | 160 | 50 |

| 4820 0160 | 160 | 194 | 40 | 180 | 52 |

| 4820 0180 | 180 | 212 | 40 | 200 | 57 |

| 4820 0200 | 200 | 194 | 40 | 230 | 52 |

| 4820 0230 | 230 | 212 | 40 | 250 | 57 |

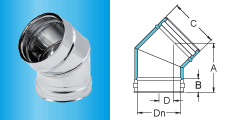

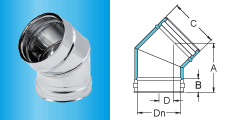

45° CURVE

Thanks to this component the vertical axis of the chimney, flue, pipe or smoke duct can be slanted 45°.

| Code | Dn | A | B | C | D |

| 4834 0080 | 80 | 159 | 40 | 100 | 48 |

| 4834 0100 | 100 | 152 | 40 | 120 | 45 |

| 4834 0120 | 120 | 152 | 40 | 140 | 45 |

| 4834 0140 | 140 | 152 | 40 | 160 | 45 |

| 4834 0160 | 160 | 169 | 40 | 180 | 52 |

| 4834 0180 | 180 | 199 | 40 | 200 | 62 |

| 4834 0200 | 200 | 169 | 40 | 230 | 52 |

| 4834 0230 | 230 | 199 | 40 | 250 | 62 |

Componente che permette di allacciare a 90° il camino, canna fumaria al canale da fumo. La particolarità di questo elemento è che viene ottenuto tramite estrusione permettendo così di poter saldare in continuo l’innesto maschio mono parete.

| Codice | Dn | A | B | C | D | E |

| 4831 0080 | 80 | 328 | 40 | 100 | 130 | 124 |

| 4831 0100 | 100 | 328 | 40 | 120 | 140 | 124 |

| 4831 0120 | 120 | 328 | 40 | 140 | 150 | 124 |

| 4831 0140 | 140 | 328 | 40 | 160 | 160 | 124 |

| 4831 0160 | 160 | 495 | 40 | 180 | 170 | 208 |

| 4831 0180 | 180 | 495 | 40 | 200 | 180 | 208 |

| 4831 0200 | 200 | 495 | 40 | 230 | 195 | 208 |

| 4831 0230 | 230 | 495 | 40 | 250 | 205 | 208 |

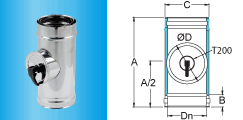

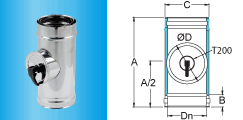

90° FITTING (MALE SINGLE-WALL COUPLING)

With this component the chimney and flue can be connected to the smoke duct at 90°. The peculiarity of this element is that it is made by extrusion meaning the single-wall male coupling can be welded without a seam.

| Code | Dn | A | B | C | A/2 |

| 4839 0080 | 80 | 328 | 40 | 100 | 164 |

| 4839 0100 | 100 | 328 | 40 | 120 | 164 |

| 4839 0120 | 120 | 328 | 40 | 140 | 164 |

| 4839 0140 | 140 | 328 | 40 | 160 | 164 |

| 4839 0160 | 160 | 328 | 40 | 180 | 164 |

| 4839 0180 | 180 | 328 | 40 | 200 | 164 |

| 4839 0200 | 200 | 328 | 40 | 230 | 164 |

| 4839 0230 | 230 | 328 | 40 | 250 | 164 |

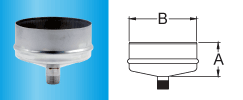

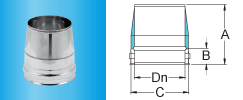

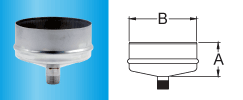

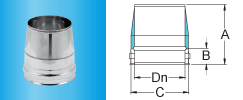

EAVES PLATE

Component to place at the base of the chimney; its peculiarity is that it is made by swaging a flat disk. Moreover, the condensate discharge is made in stainless steel, ¾” thread and is welded in place.

| Code | Dn | A | B |

| 4839 0080 | 80 | 79 | 100 |

| 4839 0100 | 100 | 82 | 120 |

| 4839 0120 | 120 | 87 | 140 |

| 4839 0140 | 140 | 91 | 160 |

| 4839 0160 | 160 | 95 | 180 |

| 4839 0180 | 180 | 98 | 200 |

| 4839 0200 | 200 | 95 | 230 |

| 4839 0230 | 230 | 109 | 250 |

INSPECTION FITTING WITH SEALING PLUG (T600)

Necessary for cleaning and maintenance work; to be placed under the connections or as prescribed by the standard. Suitable for dry and negative pressure fumes: T600-N1-D.

| Code | Dn | A | B | C | A/2 |

| 4832 0080 | 80 | 328 | 40 | 100 | 164 |

| 4832 0100 | 100 | 328 | 40 | 120 | 164 |

| 4832 0120 | 120 | 328 | 40 | 140 | 164 |

| 4832 0140 | 140 | 328 | 40 | 160 | 164 |

| 4832 0160 | 160 | 495 | 40 | 180 | 247,5 |

| 4832 0180 | 180 | 495 | 40 | 200 | 247,5 |

| 4832 0200 | 200 | 495 | 40 | 230 | 247,5 |

| 4832 0230 | 230 | 495 | 40 | 250 | 247,5 |

CONICAL CHIMNEY CAP

To be placed on the top; it does not protect against the rain, snow or wind. It allows the fumes to be discharged without obstacles or pressure losses.

| Code | Dn | A | B | C |

| 4835 0080 | 80 | 165 | 40 | 100 |

| 4835 0100 | 100 | 165 | 40 | 120 |

| 4835 0120 | 120 | 165 | 40 | 140 |

| 4835 0140 | 140 | 165 | 40 | 160 |

| 4835 0160 | 160 | 165 | 40 | 180 |

| 4835 0180 | 180 | 165 | 40 | 200 |

| 4835 0200 | 200 | 165 | 40 | 230 |

| 4835 0230 | 230 | 165 | 40 | 250 |

WINDPROOF CHIMNEY CAP

Component to place on the top; it protects against the rain, snow and wind.

| Code | Dn | A | B | C | D | E |

| 4838 0080 | 80 | 215 | 40 | 100 | 250 | 137 |

| 4838 0100 | 100 | 215 | 40 | 120 | 250 | 137 |

| 4838 0120 | 120 | 215 | 40 | 140 | 250 | 137 |

| 4838 0140 | 140 | 215 | 40 | 160 | 250 | 137 |

| 4838 0160 | 160 | 215 | 40 | 180 | 300 | 137 |

| 4838 0180 | 180 | 283 | 40 | 200 | 300 | 195 |

| 4838 0200 | 200 | 283 | 40 | 230 | 400 | 195 |

| 4838 0230 | 230 | 283 | 40 | 250 | 400 | 195 |

CHINESE CHIMNEY CAP

Component to place on the top; it provides sufficient protection against rain and snow.

| Code | Dn | A | B | C | D | E |

| 4837 0080 | 80 | 165 | 40 | 100 | 250 | 216 |

| 4837 0100 | 100 | 170 | 40 | 120 | 250 | 216 |

| 4837 0120 | 120 | 170 | 40 | 140 | 250 | 216 |

| 4837 0140 | 140 | 170 | 40 | 160 | 250 | 216 |

| 4837 0160 | 160 | 177 | 40 | 180 | 300 | 276 |

| 4837 0180 | 180 | 210 | 40 | 200 | 300 | 335 |

| 4837 0200 | 200 | 215 | 40 | 230 | 400 | 335 |

| 4837 0230 | 230 | 220 | 40 | 250 | 400 | 396 |

ADJUSTABLE WALL CHIMNEY SUPPORT

Component necessary to support the system

| Code | Dn | A | B | C | D | E | F | G | H | I |

| 4833 0080 | 80 | 160 | 40 | 100 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4833 0100 | 100 | 160 | 40 | 120 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4833 0120 | 120 | 160 | 40 | 140 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4833 0140 | 140 | 160 | 40 | 160 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4833 0160 | 160 | 160 | 40 | 180 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4833 0180 | 180 | 160 | 40 | 200 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4833 0200 | 200 | 160 | 40 | 230 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4833 0230 | 230 | 160 | 40 | 250 | 285 | 303 | 492 | 345 | 152 | 232 |

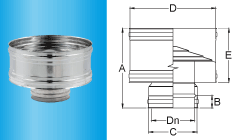

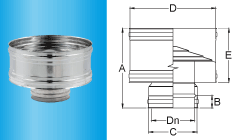

ELEMENT WITH SCREW FOR FUMES ANALYSIS

Component used for analysing single and collective fumes systems connected to Type C appliances (UNI 10641/97).

| Code | Dn | A | B | C | D |

| 4821 0080 | 80 | 245 | 40 | 100 | 122,5 |

| 4821 0100 | 100 | 245 | 40 | 120 | 122,5 |

| 4821 0120 | 120 | 245 | 40 | 140 | 122,5 |

| 4821 0140 | 140 | 245 | 40 | 160 | 122,5 |

| 4821 0160 | 160 | 245 | 40 | 180 | 122,5 |

| 4821 0180 | 180 | 245 | 40 | 200 | 122,5 |

| 4821 0200 | 200 | 245 | 40 | 230 | 122,5 |

| 4821 0230 | 230 | 245 | 40 | 250 | 122,5 |

BLACK SEALING RING (T200)

Necessary for sealing the pipe, chimney, flue and smoke duct. Colour black, conforms to EN 14241/1 T200 W2 K2.

| Code | Dn | A |

| 4021 0080 | 80 | 12 |

| 4021 0100 | 100 | 12 |

| 4021 0120 | 120 | 12 |

| 4021 0140 | 140 | 12 |

| 4021 0160 | 160 | 12 |

| 4021 0180 | 180 | 12 |

| 4021 0200 | 200 | 12 |

| 4021 0230 | 230 | 12 |

|

DARK BROWN MATT DAMASK EFFECT (RAL 8017)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN MATT DARK BROWN (RAL 8017)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN BLACKIf temperatures exceed 450° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN WHITE (RAL 9010)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |

MAIN FEATURES

MAT AIR STAINLESS STEEL

- Inner surface in 0.5mm thick AISI 316L BA stainless steel;

- Static air insulation with double crown of mineral wool on couplings (10+10);

- Outer surface in 0.5mm thick AISI 304 BA stainless steel.

MAT AIR COPPER

- Inner surface in 0.5mm thick AISI 316L BA stainless steel;

- Static air insulation with double crown of mineral wool on couplings (10+10);

- Copper outer wall.

- *Complete range for the Mat Air Inox series;

- High insulating power also for solid fuels (T600°)

- Reduced external dimensions.

MAIN FEATURES

MAT AIR STAINLESS STEEL

- Inner surface in 0.5mm thick AISI 316L BA stainless steel;

- Static air insulation with double crown of mineral wool on couplings (10+10);

- Outer surface in 0.5mm thick AISI 304 BA stainless steel.

MAT AIR COPPER

- Inner surface in 0.5mm thick AISI 316L BA stainless steel;

- Static air insulation with double crown of mineral wool on couplings (10+10);

- Copper outer wall.

- *Complete range for the Mat Air Inox series;

- High insulating power also for solid fuels (T600°)

- Reduced external dimensions.

| Material specification | |

| Inside diameter (mm)*: | 80•100•120•140•160•180•200•230 |

| Outside diameter (mm)*. | 100•120•140•160•180•200•230•250 |

| Inner surface | 0.5 mm nominal thickness Quality 1.4404 (AISI 316L stainless steel) |

| Insulation | 10 mm air gap with surface thermal resistance of 200°C equal to a dry air conductivity of: 0.026 m2K/W (300 K, 100 kPa) |

| Sealing ring | Profiled ring seal with three black silicone sealing lips conforming to UNI EN 14241/1 |

| Roughness | 1 mm average value |

| General information | |

| Installation | Internal Yes External YES it is rain proof |

| Fields of application | Pipes, chimneys, smoke ducts, flues and manifolds connected to blown air, atmospheric, condensation and pressurised boilers, type B, C appliances, fireplaces, stoves, kitchen hoods, ovens and ventilation ducts |

| Permitted fuels | T200 Gas, Diesel oil, LPG, Pellets T600 Gas, Diesel oil, LPG, Pellets and Firewood |

| Conservation | In environments with a non-corrosive atmosphere |

| Product warranty | As per the 99/44/EC directive |

| Dangerous substances | None |

| Freezing-thawing resistance | Meets UNI EN 1856-1 |

| Accidental contact | Protective shields must be used when surface temperature is greater than 70°C |

| Storage | Do not store the material near ferrous materials, premises must be dry and protected against the elements |

| Usage limits | Do not use stainless steel flue systems for premises such as laundries, dye houses, furriers, printer’s, beauty salons or where there are halogen or chromium vapours/fumes |

| Product designation as per the EN 1856-2 standard | Chimney system |

| No. of the standard | EN 1856-1 |

| Temperature level | T200 |

| Pressure level | P1 |

| Resistance to condensation | W |

| Resistance to corrosion | V2 |

| Thickness of the inner surface | L50050 |

| Resistance to fire from inside and distance from combustible materials | O (30) M |

| Product designation as per the EN 1856-2 standard: | Canale da fumo |

| No. of the standard | EN 1856-1 |

| Temperature level | T600 |

| Pressure level | N1 |

| Resistance to condensation | D |

| Resistance to corrosion | V2 |

| Thickness of the inner surface | L50050 |

| Resistance to fire from inside and distance from combustible materials | G(600) M |

| Performance required according to the designation | ||

| Temperature level | T200

T600 |

working with a nominal fumes temperature at less than 200°C working with a nominal fumes temperature at less than 600°C |

| Pressure level | P1

N1 |

working with a positive and negative pressure up to 200Pa. Permitted loss less than 0.006 l/m2 working with a positive and negative pressure up to 40Pa. Permitted loss less than 2.0l/sm2 |

| Resistance to condensation | W

D |

working with moist and dry fumes working with dry fumes |

| Resistance to corrosion | V2 | working with Gas-Diesel oil-LPG-Pellets-Firewood |

| Specification of the inner surface | L50 | 1.4404 (AISI 316L stainless steel) |

| Thickness of the inner surface | 050 | spessore nominale 0,5 mm |

| Resistance to fire from inside | O

G |

not fire resistant from inside resistant to fire from inside |

| Distance from combustible materials | (30)

(600) |

(30)=minimum 30mm; (600)=minimum 600mm; |

INSTALLATION INSTRUCTIONS

- Position the elements as shown by the arrow printed on the label and on the piece.

- With use at T200_P1_W put the sealing ring in place on the female socket.

- The three lips of the sealing ring must be facing the inside of the pipe.

- Use some talcum powder or soap to make it easier to put the ring in place and also to prevent damaging it.

- If T600_N1_D is used, use the product without the sealing ring.

- Once the pieces are in place, mount and tighten the locking clamp on each join.

- Observe the compression loads and the non-vertical installations.

- Avoid the build-up of condensation or soot which could be the cause of corrosion. Also avoid horizontal sections; nonetheless install the elements with the longitudinal welding facing up (3% gradient).

ESSENTIAL FEATURES

Resistance to the wind load:

- Distance between wall brackets: 2 m

- Free length from the last bracket: 1.5 m

Compressive strength:

- Linear elements’ maximum load: 12m

- Maximum load of a straight fitting at 90°: 12m

- Maximum load of the wall chimney support: 5m

Note: these values refer to the worst conditions. For more info see (Mechanical Strength Table)

30m Tensile and bending strength (linear elements):

- Maximum load at traction (element connection means and chimney connections): 3m

- Non-vertical installations: max. 45°

- Non-vertical installations: distance between wall chimney supports = 2m

Traction and bending strength (non-linear elements):

- Non-vertical installations: NPD

FLUE SYSTEM MAINTENANCE

Scheduled maintenance carried out by qualified personnel:

- Unless standards dictate otherwise or different agreements are reached with the user, the following maintenance schedule is advisable:

- gaseous fuels: 1 / year;

- liquid fuels: 1 / 6 months;

- solid fuels: 1 / month.

- Clean the smoke duct with a soft plastic brush or sponge as well as the equipment compartment for pipe supply and ventilation, the inspection fitting and chimney and also make sure the smoke/fumes and condensates etc., are flowing freely.

SYSTEM COMPONENTS

1 M LINEAR ELEMENT

995 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4810 0080 | 80 | 995 | 40 | 100 |

| 4810 0100 | 100 | 995 | 40 | 120 |

| 4810 0120 | 120 | 995 | 40 | 140 |

| 4810 0140 | 140 | 995 | 40 | 160 |

| 4810 0160 | 160 | 995 | 40 | 180 |

| 4810 0180 | 180 | 995 | 40 | 200 |

| 4810 0200 | 200 | 995 | 40 | 230 |

| 4810 0230 | 230 | 995 | 40 | 250 |

0.5 M LINEAR ELEMENT

495 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4805 0080 | 80 | 495 | 40 | 100 |

| 4805 0100 | 100 | 495 | 40 | 120 |

| 4805 0120 | 120 | 495 | 40 | 140 |

| 4805 0140 | 140 | 495 | 40 | 160 |

| 4805 0160 | 160 | 495 | 40 | 180 |

| 4805 0180 | 180 | 495 | 40 | 200 |

| 4805 0200 | 200 | 495 | 40 | 230 |

| 4805 0230 | 230 | 495 | 40 | 250 |

0.25 M LINEAR ELEMENT

245 mm high modular component to use on vertical or sub-horizontal sections. It must be applied as shown by the arrow printed on the label.

| Code | Dn | A | B | C |

| 4802 0080 | 80 | 245 | 40 | 100 |

| 4802 0100 | 100 | 245 | 40 | 120 |

| 4802 0120 | 120 | 245 | 40 | 140 |

| 4802 0140 | 140 | 245 | 40 | 160 |

| 4802 0160 | 160 | 245 | 40 | 180 |

| 4802 0180 | 180 | 245 | 40 | 200 |

| 4802 0200 | 200 | 245 | 40 | 230 |

| 4802 0230 | 230 | 245 | 40 | 250 |

LINEAR TELESCOPIC ELEMENT FROM 0.5 TO 0.95

To use for completing sub-horizontal sections where standard linear elements cannot be used due to the enforced distance. It is indispensable to use a chimney support (art. 4567) in the case of vertical sections (above them). Product designation T450 N1 D V2 L50050 G(600).

| Code | Dn | A | B | C | D |

| 4822 0080 | 80 | 550 | 40 | 100 | 900 |

| 4822 0100 | 100 | 550 | 40 | 120 | 900 |

| 4822 0120 | 120 | 550 | 40 | 140 | 900 |

| 4822 0140 | 140 | 550 | 40 | 160 | 900 |

| 4822 0160 | 160 | 550 | 40 | 180 | 900 |

| 4822 0180 | 180 | 550 | 40 | 200 | 900 |

| 4822 0200 | 200 | 550 | 40 | 230 | 900 |

| 4822 0230 | 230 | 550 | 40 | 250 | 900 |

30° CURVE

Thanks to this component the vertical axis of the chimney, flue, pipe or smoke duct can be slanted 30°.

| Code | Dn | A | B | C | D |

| 4820 0080 | 80 | 187 | 40 | 100 | 50 |

| 4820 0100 | 100 | 179 | 40 | 120 | 48 |

| 4820 0120 | 120 | 170 | 40 | 140 | 45 |

| 4820 0140 | 140 | 187 | 40 | 160 | 50 |

| 4820 0160 | 160 | 194 | 40 | 180 | 52 |

| 4820 0180 | 180 | 212 | 40 | 200 | 57 |

| 4820 0200 | 200 | 194 | 40 | 230 | 52 |

| 4820 0230 | 230 | 212 | 40 | 250 | 57 |

45° CURVE

Thanks to this component the vertical axis of the chimney, flue, pipe or smoke duct can be slanted 45°.

| Code | Dn | A | B | C | D |

| 4834 0080 | 80 | 159 | 40 | 100 | 48 |

| 4834 0100 | 100 | 152 | 40 | 120 | 45 |

| 4834 0120 | 120 | 152 | 40 | 140 | 45 |

| 4834 0140 | 140 | 152 | 40 | 160 | 45 |

| 4834 0160 | 160 | 169 | 40 | 180 | 52 |

| 4834 0180 | 180 | 199 | 40 | 200 | 62 |

| 4834 0200 | 200 | 169 | 40 | 230 | 52 |

| 4834 0230 | 230 | 199 | 40 | 250 | 62 |

Componente che permette di allacciare a 90° il camino, canna fumaria al canale da fumo. La particolarità di questo elemento è che viene ottenuto tramite estrusione permettendo così di poter saldare in continuo l’innesto maschio mono parete.

| Codice | Dn | A | B | C | D | E |

| 4831 0080 | 80 | 328 | 40 | 100 | 130 | 124 |

| 4831 0100 | 100 | 328 | 40 | 120 | 140 | 124 |

| 4831 0120 | 120 | 328 | 40 | 140 | 150 | 124 |

| 4831 0140 | 140 | 328 | 40 | 160 | 160 | 124 |

| 4831 0160 | 160 | 495 | 40 | 180 | 170 | 208 |

| 4831 0180 | 180 | 495 | 40 | 200 | 180 | 208 |

| 4831 0200 | 200 | 495 | 40 | 230 | 195 | 208 |

| 4831 0230 | 230 | 495 | 40 | 250 | 205 | 208 |

90° FITTING (MALE SINGLE-WALL COUPLING)

With this component the chimney and flue can be connected to the smoke duct at 90°. The peculiarity of this element is that it is made by extrusion meaning the single-wall male coupling can be welded without a seam.

| Code | Dn | A | B | C | A/2 |

| 4839 0080 | 80 | 328 | 40 | 100 | 164 |

| 4839 0100 | 100 | 328 | 40 | 120 | 164 |

| 4839 0120 | 120 | 328 | 40 | 140 | 164 |

| 4839 0140 | 140 | 328 | 40 | 160 | 164 |

| 4839 0160 | 160 | 328 | 40 | 180 | 164 |

| 4839 0180 | 180 | 328 | 40 | 200 | 164 |

| 4839 0200 | 200 | 328 | 40 | 230 | 164 |

| 4839 0230 | 230 | 328 | 40 | 250 | 164 |

EAVES PLATE

Component to place at the base of the chimney; its peculiarity is that it is made by swaging a flat disk. Moreover, the condensate discharge is made in stainless steel, ¾” thread and is welded in place.

| Code | Dn | A | B |

| 4839 0080 | 80 | 79 | 100 |

| 4839 0100 | 100 | 82 | 120 |

| 4839 0120 | 120 | 87 | 140 |

| 4839 0140 | 140 | 91 | 160 |

| 4839 0160 | 160 | 95 | 180 |

| 4839 0180 | 180 | 98 | 200 |

| 4839 0200 | 200 | 95 | 230 |

| 4839 0230 | 230 | 109 | 250 |

INSPECTION FITTING WITH SEALING PLUG (T600)

Necessary for cleaning and maintenance work; to be placed under the connections or as prescribed by the standard. Suitable for dry and negative pressure fumes: T600-N1-D.

| Code | Dn | A | B | C | A/2 |

| 4832 0080 | 80 | 328 | 40 | 100 | 164 |

| 4832 0100 | 100 | 328 | 40 | 120 | 164 |

| 4832 0120 | 120 | 328 | 40 | 140 | 164 |

| 4832 0140 | 140 | 328 | 40 | 160 | 164 |

| 4832 0160 | 160 | 495 | 40 | 180 | 247,5 |

| 4832 0180 | 180 | 495 | 40 | 200 | 247,5 |

| 4832 0200 | 200 | 495 | 40 | 230 | 247,5 |

| 4832 0230 | 230 | 495 | 40 | 250 | 247,5 |

CONICAL CHIMNEY CAP

To be placed on the top; it does not protect against the rain, snow or wind. It allows the fumes to be discharged without obstacles or pressure losses.

| Code | Dn | A | B | C |

| 4835 0080 | 80 | 165 | 40 | 100 |

| 4835 0100 | 100 | 165 | 40 | 120 |

| 4835 0120 | 120 | 165 | 40 | 140 |

| 4835 0140 | 140 | 165 | 40 | 160 |

| 4835 0160 | 160 | 165 | 40 | 180 |

| 4835 0180 | 180 | 165 | 40 | 200 |

| 4835 0200 | 200 | 165 | 40 | 230 |

| 4835 0230 | 230 | 165 | 40 | 250 |

WINDPROOF CHIMNEY CAP

Component to place on the top; it protects against the rain, snow and wind.

| Code | Dn | A | B | C | D | E |

| 4838 0080 | 80 | 215 | 40 | 100 | 250 | 137 |

| 4838 0100 | 100 | 215 | 40 | 120 | 250 | 137 |

| 4838 0120 | 120 | 215 | 40 | 140 | 250 | 137 |

| 4838 0140 | 140 | 215 | 40 | 160 | 250 | 137 |

| 4838 0160 | 160 | 215 | 40 | 180 | 300 | 137 |

| 4838 0180 | 180 | 283 | 40 | 200 | 300 | 195 |

| 4838 0200 | 200 | 283 | 40 | 230 | 400 | 195 |

| 4838 0230 | 230 | 283 | 40 | 250 | 400 | 195 |

CHINESE CHIMNEY CAP

Component to place on the top; it provides sufficient protection against rain and snow.

| Code | Dn | A | B | C | D | E |

| 4837 0080 | 80 | 165 | 40 | 100 | 250 | 216 |

| 4837 0100 | 100 | 170 | 40 | 120 | 250 | 216 |

| 4837 0120 | 120 | 170 | 40 | 140 | 250 | 216 |

| 4837 0140 | 140 | 170 | 40 | 160 | 250 | 216 |

| 4837 0160 | 160 | 177 | 40 | 180 | 300 | 276 |

| 4837 0180 | 180 | 210 | 40 | 200 | 300 | 335 |

| 4837 0200 | 200 | 215 | 40 | 230 | 400 | 335 |

| 4837 0230 | 230 | 220 | 40 | 250 | 400 | 396 |

ADJUSTABLE WALL CHIMNEY SUPPORT

Component necessary to support the system

| Code | Dn | A | B | C | D | E | F | G | H | I |

| 4833 0080 | 80 | 160 | 40 | 100 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4833 0100 | 100 | 160 | 40 | 120 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4833 0120 | 120 | 160 | 40 | 140 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4833 0140 | 140 | 160 | 40 | 160 | 202 | 220 | 367 | 262 | 110 | 190 |

| 4833 0160 | 160 | 160 | 40 | 180 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4833 0180 | 180 | 160 | 40 | 200 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4833 0200 | 200 | 160 | 40 | 230 | 285 | 303 | 492 | 345 | 152 | 232 |

| 4833 0230 | 230 | 160 | 40 | 250 | 285 | 303 | 492 | 345 | 152 | 232 |

ELEMENT WITH SCREW FOR FUMES ANALYSIS

Component used for analysing single and collective fumes systems connected to Type C appliances (UNI 10641/97).

| Code | Dn | A | B | C | D |

| 4821 0080 | 80 | 245 | 40 | 100 | 122,5 |

| 4821 0100 | 100 | 245 | 40 | 120 | 122,5 |

| 4821 0120 | 120 | 245 | 40 | 140 | 122,5 |

| 4821 0140 | 140 | 245 | 40 | 160 | 122,5 |

| 4821 0160 | 160 | 245 | 40 | 180 | 122,5 |

| 4821 0180 | 180 | 245 | 40 | 200 | 122,5 |

| 4821 0200 | 200 | 245 | 40 | 230 | 122,5 |

| 4821 0230 | 230 | 245 | 40 | 250 | 122,5 |

BLACK SEALING RING (T200)

Necessary for sealing the pipe, chimney, flue and smoke duct. Colour black, conforms to EN 14241/1 T200 W2 K2.

| Code | Dn | A |

| 4021 0080 | 80 | 12 |

| 4021 0100 | 100 | 12 |

| 4021 0120 | 120 | 12 |

| 4021 0140 | 140 | 12 |

| 4021 0160 | 160 | 12 |

| 4021 0180 | 180 | 12 |

| 4021 0200 | 200 | 12 |

| 4021 0230 | 230 | 12 |

|

DARK BROWN MATT DAMASK EFFECT (RAL 8017)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN MATT DARK BROWN (RAL 8017)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN BLACKIf temperatures exceed 450° (on the outer surface) the paint could flake and come off. |

|

OUTER SURFACE FINISH IN WHITE (RAL 9010)If temperatures exceed 250° (on the outer surface) the paint could flake and come off. |